Modern Healthcare Inventory Management Systems for Logistics

Efficient healthcare inventory management is essential for logistics-driven medical supply chains. For pharmaceutical distributors and large-scale hospital systems, managing medical stock with real-time accuracy can directly impact both patient care and operational efficiency. While many providers turn to off-the-shelf inventory software, these options often fall short in complex healthcare environments. This article explores what makes a robust medical stock management system and why custom-built solutions are increasingly vital for the healthcare logistics sector.

- 1. The Role of Logistics in Healthcare Inventory Management

- 2. Limitations of Off-the-Shelf Medical Inventory Management

- 3. Why Custom Healthcare Inventory Management Systems Work Better

- 4. Key Features of a Custom Medical Stock Management System

- 5. Benefits of Custom Inventory Management in Healthcare Industry

- 6. Choosing a Software Partner for Healthcare Inventory Projects

- Conclusion

1. The Role of Logistics in Healthcare Inventory Management

1.1. How Logistics Affects Medical Inventory Accuracy

Logistical accuracy is essential to maintaining efficient healthcare inventory. Without visibility into stock levels and movement, delays and errors become inevitable. A centralized, digital healthcare inventory management system bridges this gap by enabling real-time tracking and interdepartmental coordination.

Modern inventory solutions also integrate with barcoding, RFID, and GPS technologies to support precise shipment updates. As hospital networks and suppliers expand their operations, having a responsive and connected inventory system is no longer optional, it’s foundational.

1.2. Challenges in Medical Product Transportation and Storage

Transporting medical products poses unique challenges. Many items are sensitive to temperature, humidity, and handling. Missteps in any part of the journey can result in unusable stock. This necessitates that inventory systems work in harmony with logistics platforms to monitor conditions in transit.

In multi-location networks, syncing data between warehouses and distribution centers is another major hurdle. A traditional software solution cannot often integrate these elements fluidly. Therefore, healthcare inventory management must support intelligent routing, location-based tracking, and predictive stocking capabilities.

1.3. Why Real-Time Tracking Is Critical for Healthcare Providers

Real-time inventory tracking ensures that decision-makers can act promptly. Whether it’s restocking ventilators in an ICU or distributing vaccines to rural clinics, immediate insights prevent costly delays. A robust medical inventory management system must offer visibility not only across stock levels but also in transport routes and delivery statuses.

For example, the CDC reported during the COVID-19 pandemic that over 20% of wasted doses resulted from logistical mismanagement. Real-time inventory solutions would have helped anticipate shortfalls and reroute supplies accordingly. This demonstrates how vital inventory accuracy is to effective healthcare delivery.

2. Limitations of Off-the-Shelf Medical Inventory Management

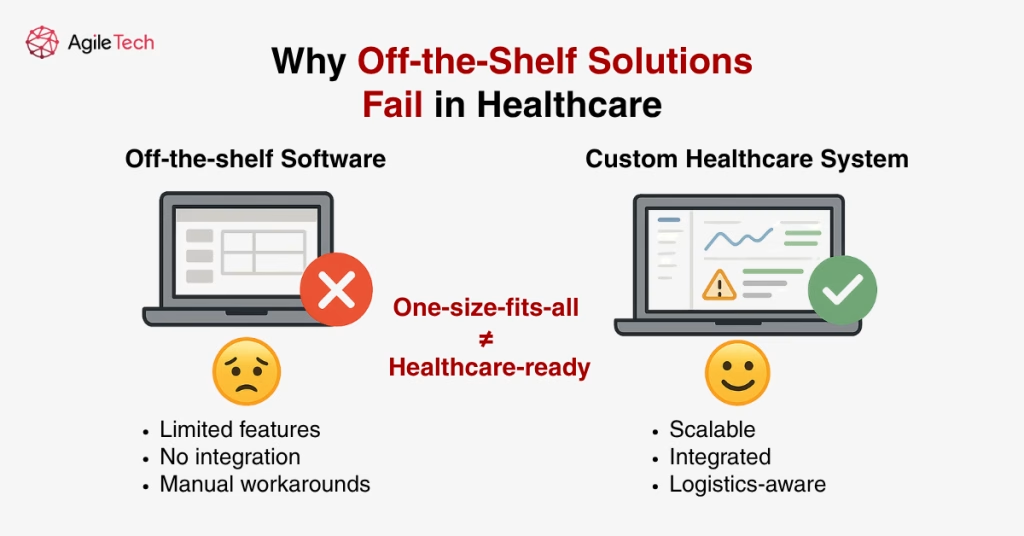

Prebuilt inventory software may seem attractive for its quick deployment and lower upfront cost. However, such solutions often lack the flexibility required by large-scale medical networks or specialized pharmaceutical distributors. Healthcare logistics requires tailored functionality, which packaged systems typically cannot provide.

Off-the-shelf tools often come with predefined workflows that may not align with a hospital’s or supplier’s internal processes. As a result, staff may resort to manual workarounds, increasing the risk of errors and inefficiencies. Additionally, these systems rarely provide deep integrations with existing CRM platforms or ERP systems used in medical logistics.

2.1. One-Size-Fits-All Software Doesn’t Fit Healthcare

Healthcare operations are too diverse for generic inventory platforms. Consider a hospital group that manages supplies across 25 locations. A static platform cannot support regional nuances like varying delivery frequencies or different compliance requirements. The same issue arises in pharmaceutical distribution, where each state or region may enforce different storage protocols.

In contrast, custom inventory management systems are built to reflect specific needs, workflows, and regulations. This tailored approach results in better efficiency, higher adoption rates, and stronger compliance with health standards.

2.2. Lack of Flexibility in Managing Diverse Medical Stock

From surgical tools to temperature-sensitive vaccines, medical stock spans a broad range of categories. Prebuilt systems often struggle to track such diversity. If a solution cannot distinguish between stock types or manage them under different handling protocols, it poses serious risks.

A healthcare inventory management system must offer flexible categorization, intelligent batch control, and compatibility with environmental sensors. Without these features, inventory personnel may miss expiration dates, storage anomalies, or replenishment triggers, leading to shortages or regulatory issues.

2.3. Integration Gaps with Transportation and ERP Systems

Another limitation of standard software is the inability to connect with broader logistics ecosystems. Most healthcare providers and suppliers already use multiple tools: ERPs for finance, CRMs for vendor relations, and logistics software for fleet management. Without smooth integration, data silos emerge.

Custom-built inventory management solutions offer API-based integration, enabling unified dashboards and better decision-making. A logistics manager can view inbound shipments, warehouse availability, and procurement schedules in one place, a capability that off-the-shelf tools usually lack.

3. Why Custom Healthcare Inventory Management Systems Work Better

Custom inventory systems are designed to match the real-world logistics and operational needs of the healthcare sector. From configuring specialized workflows to embedding transport data, these systems close the gaps that generic software creates.

Customization ensures the inventory system aligns with how a business or hospital operates. Whether it’s barcode printing for specific stock types or automatic restocking alerts based on transport delivery intervals, the flexibility is key to scalability and compliance.

3.1. Tailored Solutions for Multi-Warehouse Operations

Large hospital chains or suppliers operating across several regions need centralized control with local flexibility. A custom system can provide both. For instance, a central dashboard may monitor total inventory, while local branches access tools for specific stock inputs and outputs.

This dual-layer approach reduces communication lags and ensures standardized procedures without ignoring site-specific needs. In one case study, a Southeast Asian hospital chain reduced inventory discrepancies by 30% after adopting a custom stock management platform that coordinated with logistics partners.

3.2. Built-in Logistics Features for Supply Chain Control

Supply chain control goes beyond tracking stock levels. It requires predicting shortages, adjusting shipments, and ensuring compliance with transit regulations. Custom inventory management systems can include route optimization tools, cold-chain compliance alerts, and automated replenishment triggers tied to delivery schedules.

For medical product companies, this level of control improves service quality and reduces penalties associated with delays or non-compliance. This is especially crucial for cross-border logistics, where transportation timelines can be unpredictable.

3.3. Supporting Growth Across Hospital Networks and Pharma Chains

As organizations grow, so do their logistical complexities. Custom software evolves with the organization. Unlike static systems, custom platforms can expand to include new facilities, departments, or international suppliers without compromising performance.

Moreover, custom systems can implement user roles, audit logs, and compliance tracking features to meet both local and international regulatory requirements. For scaling operations, this adaptability is non-negotiable.

4. Key Features of a Custom Medical Stock Management System

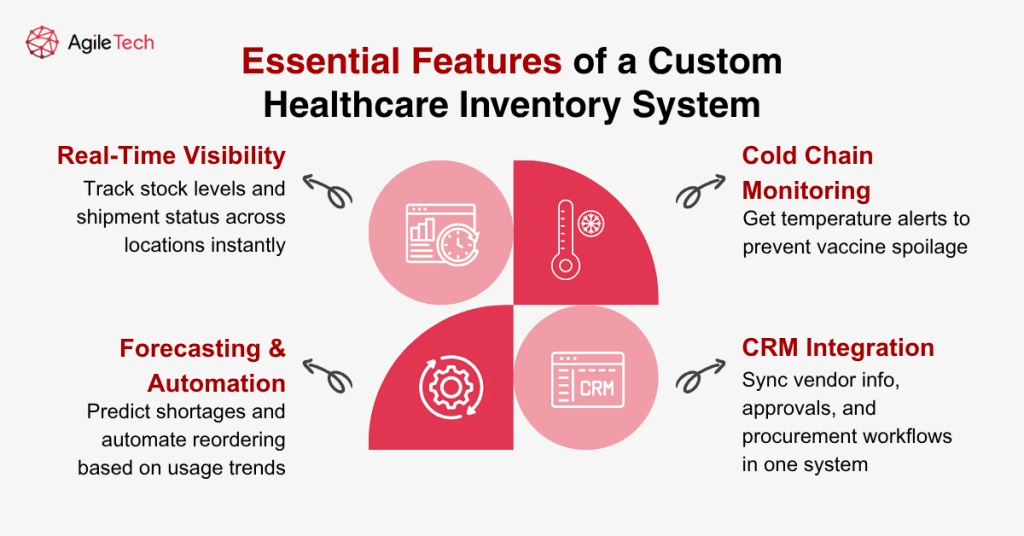

A high-performing custom medical inventory system should deliver more than basic tracking. It must embed smart logistics features that help manage dynamic supply chains. Some key features include environmental monitoring, predictive restocking, and CRM integration.

These features are designed not just for visibility but for action. They allow decision-makers to proactively handle stock imbalances and streamline procurement processes.

4.1. Batch Tracking, Expiry Alerts & Cold Chain Monitoring

In the healthcare industry, traceability is crucial. Systems should support batch-level tracking with detailed history, allowing administrators to trace any item back to its source or destination. Expiry alerts reduce the risk of administering expired products.

Cold chain monitoring adds another layer of safety. For vaccines or biologics, the system must log temperature data throughout transport and storage. Any breach should trigger automatic alerts and corrective actions.

4.2. Transport-Linked Inventory Forecasting

Predictive analytics linked to transport data allows companies to forecast stock needs based on shipment arrivals, historical usage, and seasonal trends. For example, a system might flag that surgical masks run low every winter in urban centers, prompting early procurement.

This level of forecasting reduces emergency orders, avoids costly air shipments, and ensures continuity of care. Transportation-linked forecasting is one of the strongest advantages of a logistics-aware healthcare inventory management system.

4.3. CRM Integration for Procurement and Vendor Management

Procurement in healthcare often involves multiple vendors, approval cycles, and budget considerations. Integrating CRM functionality within the inventory system enables smoother vendor communication, faster approvals, and clearer records of purchase history.

For instance, a vendor delay can be flagged within the system and rerouted to another supplier automatically. Custom systems can also support vendor scoring based on performance, improving long-term supply reliability.

Read more: How to Build a Software Inventory Management System: Key Features, Costs, and Development Guide

5. Benefits of Custom Inventory Management in Healthcare Industry

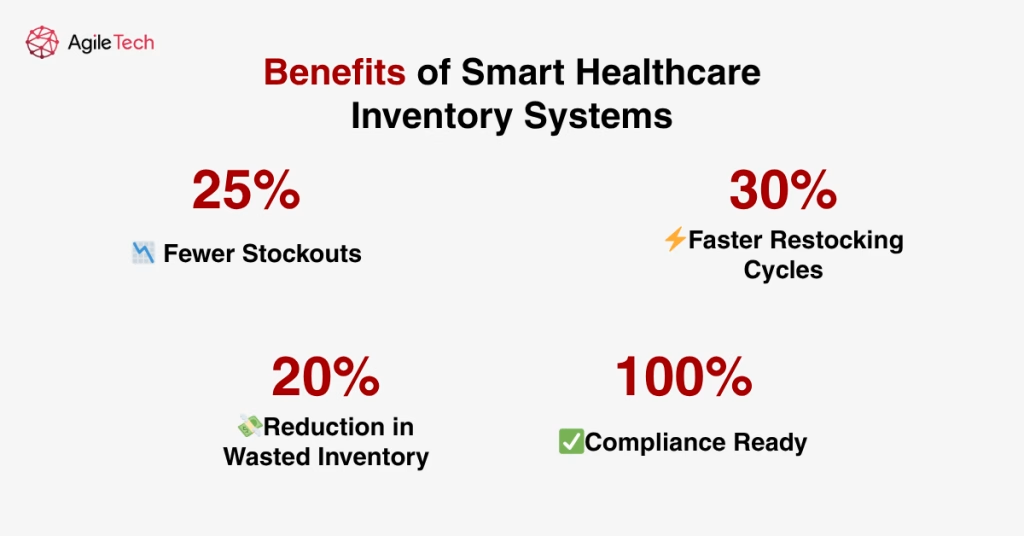

Adopting a custom inventory management system offers measurable advantages across operational, financial, and compliance areas. Hospitals and distributors gain agility, while logistics teams enjoy better control and communication.

This transformation helps organizations reduce waste, meet regulatory requirements, and adapt to fast-changing healthcare demands.

5.1. Faster Turnover and Fewer Stockouts

When logistics and inventory are synchronized, stock turnover improves. With real-time data on deliveries and consumption, replenishment cycles become more efficient. This ensures that high-demand items are always available, preventing treatment delays.

A 2022 Deloitte report found that hospitals with automated inventory tracking saw 25% fewer stockouts compared to those with manual systems. This directly impacts patient outcomes and operational trust.

5.2. Reduced Losses from Spoilage and Delays

Mismanaged transportation can lead to spoilage, particularly for perishable items. Inventory systems that monitor environmental conditions and expiration dates can help prevent such losses. Alerts and automation further reduce human error.

Combined with transportation data, these systems also detect bottlenecks. For instance, if a shipment is stuck in transit, the system can trigger emergency restocking or rerouting options. This agility minimizes disruption.

5.3. Improved Compliance and Operational Transparency

Healthcare regulations are strict, especially regarding traceability and patient safety. A robust inventory management system maintains detailed logs, supports audit readiness, and provides complete transparency across departments and locations.

With built-in compliance features, hospitals and suppliers can more easily meet FDA, WHO, or local health authority requirements. This reduces legal risk and builds trust with partners and patients alike.

Read more: Inventory Management Software Cost in 2025: What You Should Know

6. Choosing a Software Partner for Healthcare Inventory Projects

When it comes to implementing a high-performing healthcare inventory management system, AgileTech is a trusted technology partner with proven experience in logistics-focused healthcare software development. With a strong portfolio of custom-built platforms for hospital networks, pharmaceutical distributors, and medical supply chains, AgileTech brings both technical expertise and industry insight to every project.

AgileTech collaborates closely with clients to design scalable, secure, and compliant solutions tailored to their operational model. Their agile development approach ensures rapid deployment, continuous improvement, and full alignment with real-world needs in the healthcare logistics sector.

6.1. Industry Experience in Medical Logistics

AgileTech has delivered inventory management solutions for healthcare clients across Southeast Asia, Europe, and the U.S., each with unique compliance frameworks and distribution challenges. Their teams understand how to embed logistics capabilities such as transport tracking, cold chain monitoring, and ERP integration into a seamless inventory system. This industry-specific expertise enables them to anticipate challenges and engineer smarter, more durable systems.

6.2. Ability to Build Scalable, Modular Solutions

AgileTech designs systems that grow with your operation. Using modular architecture, they enable healthcare providers and suppliers to expand their systems over time adding new features, scaling to additional warehouses, or integrating third-party logistics platforms without disrupting operations. This flexibility is essential for healthcare companies that expect to expand regionally or across borders.

6.3. Long-Term Support and Customization Commitment

Beyond development, AgileTech offers robust after-sales service, including system maintenance, feature upgrades, and compliance updates. Their dedicated support team ensures your inventory management system remains aligned with changing business needs and industry standards. AgileTech’s long-term commitment to customization and reliability makes them an ideal partner for organizations seeking sustainable digital transformation in healthcare logistics.

Conclusion

In a logistics-heavy healthcare landscape, generic inventory systems often fail to meet operational demands. Custom healthcare inventory management systems fill these gaps by offering flexibility, integration, and control. From enhancing compliance to improving supply chain visibility, these systems empower both hospitals and medical suppliers to operate with confidence and precision.

As supply chains grow more complex and healthcare needs evolve, investing in custom-built inventory solutions is not just a technological decision is a strategic one.