How to Integrate Procurement System with ERP for Seamless Supply Chain [Updated 2025]

Wondering how to integrate the procurement system with ERP? In today’s digital landscape, businesses aiming to optimize purchasing operations and drive supply chain efficiency must adopt robust ERP integration strategies. This guide will walk you through the essentials of ERP-procurement integration and how it enhances supply chain performance.

- 1. Why ERP Integration Matters in Procurement and Supply Chain

- 2. Key Benefits of Integrating Procurement with ERP

- 3. Common Challenges in Procurement and ERP Integration

- 4. Step-by-Step Guide: How to Integrate Procurement System with ERP

- 5. AgileTech’s Procurement System – Ready for ERP Integration

- 6. Conclusion

1. Why ERP Integration Matters in Procurement and Supply Chain

ERP systems act as the backbone of organizational operations, housing essential functions from finance to inventory management. When procurement is integrated into this ecosystem through ERP integration, it ensures that purchasing decisions are not made in isolation but are guided by comprehensive enterprise data. This level of synchronization improves forecast accuracy and helps avoid duplicated efforts across business units.

In industries such as retail, manufacturing, and logistics, integrating procurement with ERP also allows organizations to maintain optimal inventory levels. By leveraging supply chain management ERP software, this balance prevents both overstock and stockouts, ensuring operational continuity. Procurement teams can plan and prioritize purchases more strategically when they have direct access to ERP-generated forecasts and financial data, strengthening the connection between ERP and supply chain operations.

2. Key Benefits of Integrating Procurement with ERP

seamless ERP integration, businesses can set up automated alerts for price changes, supplier delivery trends, or budget threshold breaches, enabling proactive decision-making. When combined with supply chain management ERP software, this approach enhances visibility and ensures that procurement aligns with broader operational goals. Additionally, leveraging ERP and supply chain data improves forecast accuracy, strengthens supplier negotiations, and reduces time spent reconciling information across departments. By adopting advanced ERP supply chain software, organizations gain better data quality and agility in procurement, driving both efficiency and resilience.

Further enhancing this value, ERP integration empowers organizations to implement proactive procurement strategies. With procurement data synchronized across the enterprise, analytics can identify savings opportunities, supplier risks, and performance trends in real time.

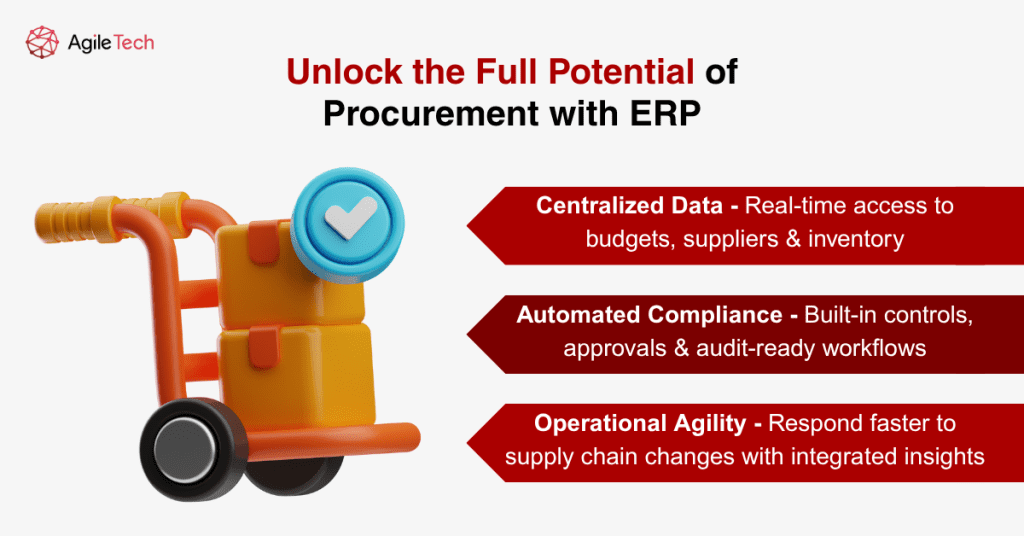

2.1. Centralized Procurement Data

Integrating procurement software with ERP systems delivers measurable advantages. First, it consolidates all procurement data into a central platform, enabling faster and smarter decision-making. Procurement teams can access real-time data about suppliers, order statuses, inventory levels, and budgets without toggling between systems. This real-time synchronization ensures transparency and streamlines communication across business units.

2.2. Automated Compliance and Controls

This streamlined data flow reduces delays, mitigates risks, and promotes compliance with purchasing policies. Modern ERP supply chain software supports automatic budget validation, multi-level approval workflows, and audit trails, reducing the chances of errors or fraud. When integrated with supply chain management ERP software, these features strengthen transparency and accountability across the entire procurement process. Built-in controls within ERP and supply chain solutions ensure that every procurement transaction is compliant with internal policies and external regulations, while seamless ERP integration further enhances efficiency and control.

Additionally, organizations can monitor supplier performance and contract adherence, which promotes accountability and improves vendor relationships. These benefits are particularly vital in highly regulated industries such as pharmaceuticals or aerospace.

2.3. Agile Response to Market Changes

Supply chain management ERP software empowers companies to respond swiftly to disruptions such as supplier delays, market volatility, or demand surges. Procurement and ERP systems working in tandem allow for adaptive planning based on live data.

For instance, if a key material becomes unavailable, the integrated system can immediately identify alternate suppliers, recalculate costs, and adjust delivery timelines. This level of responsiveness gives businesses a competitive edge in uncertain markets and supports business continuity planning.

3. Common Challenges in Procurement and ERP Integration

Scalability is another concern, especially for growing businesses. An ERP integration that works at a small scale might struggle under the pressure of added suppliers, SKUs, or business units. Companies should future-proof their ERP supply chain software architecture to avoid rework and additional costs as they expand. Moreover, inconsistent terminology or field definitions between systems can lead to misinterpretation of critical data, highlighting the importance of well-structured supply chain management ERP software to ensure accuracy and efficiency across the organization.

Even though the business case for ERP integration is strong, many organizations struggle with execution due to unclear ownership and a lack of long-term vision. Integration projects that focus solely on technical configuration often miss the bigger picture, aligning people, processes, and culture.

3.1. System Compatibility Issues

Despite the clear benefits, ERP integration with procurement platforms presents some challenges. One major issue is the lack of compatibility between legacy procurement systems and modern ERP tools. Many older procurement applications use outdated data structures or formats, making real-time integration difficult or impossible.

Data silos are a frequent result, where departments operate with conflicting or outdated information. This leads to duplication, inconsistency, and inefficiency. Bridging this gap often requires custom development, middleware, or even a complete system overhaul.

3.2. Workflow Inconsistencies

Another major challenge is inconsistent procurement workflows across departments or regions. One team may use a centralized approval model while another follows a manual, localized approach. These discrepancies complicate ERP integration, as a standardized workflow is essential for automation and accurate reporting.

Moreover, organizations may not have documented procurement processes, making it harder to define integration rules and logic. Successful integration requires process mapping and a commitment to change management across teams.

3.3. User Adoption and Training

User resistance is a common but underestimated barrier. Employees accustomed to manual systems may be hesitant to adopt automated tools, fearing job displacement or complexity. Without adequate training, users may bypass the integrated system or misuse its features, undermining its effectiveness.

To overcome this, companies must invest in user training and communication. Demonstrating the personal benefits of ERP supply chain software, such as time savings, fewer manual tasks, and clearer data, can significantly improve adoption rates. Engaging users early in the integration project also builds ownership and reduces resistance.

Read more: ERP Procurement Optimization: Breakthrough Solution for Transportation & Logistics Enterprises

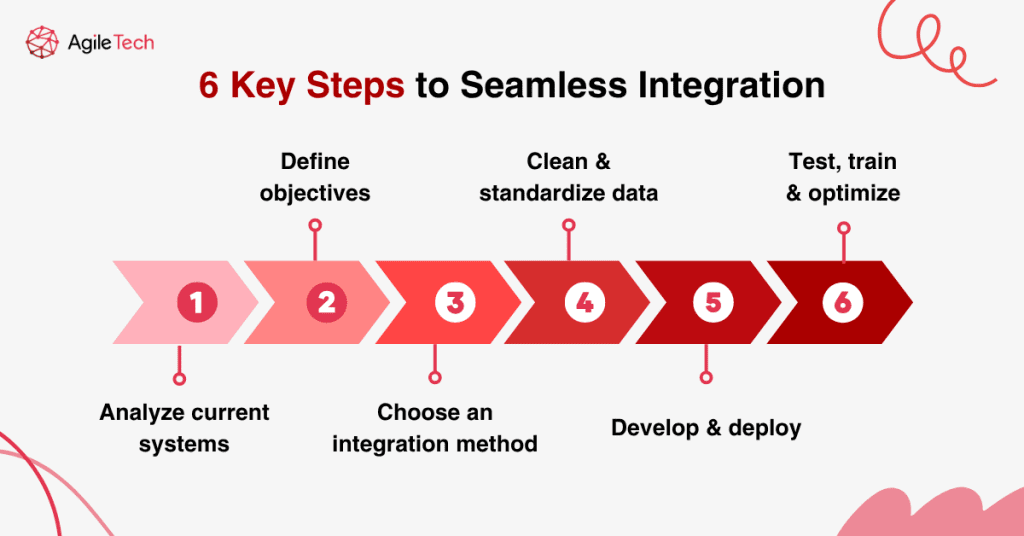

4. Step-by-Step Guide: How to Integrate Procurement System with ERP

Successful integration begins with a strategic mindset. Companies should consider both short-term deliverables and long-term goals, including system flexibility, user scalability, and ease of future upgrades. Partnering with ERP and procurement experts can also accelerate the journey and ensure compliance with industry standards.

It’s crucial to approach integration not as a one-time technical task, but as a strategic transformation journey. Beyond just linking software systems, successful integration drives operational change, eliminates redundancies, and lays the foundation for data-driven procurement.

Step 1: Analyze Your Current Procurement and ERP Systems

Begin by evaluating the tools and platforms currently in use. Document your procurement workflows and identify points where data exchange with the ERP system is necessary. Understanding these touchpoints helps define the scope of the integration.

Also, assess the limitations of your existing systems. For example, does your procurement software support data exports compatible with your ERP system? Are both platforms cloud-based or on-premise? These factors will shape your integration approach.

Step 2: Define Clear Integration Objectives

The next step is to define what success looks like. Do you want to eliminate manual data entry? Reduce procurement cycle times? Improve compliance? Align these goals with your broader supply chain management strategy.

Get stakeholders from IT, procurement, finance, and supply chain involved early. Their input ensures the ERP integration meets the real needs of users across the organization. Having measurable KPIs, such as a reduction in PO processing time or improved order accuracy, can keep the project focused and results-driven.

Step 3: Select the Right Integration Method

Several integration methods are available depending on your systems’ capabilities. API-based integration offers real-time communication between procurement and ERP systems. Middleware solutions, on the other hand, act as a translator and bridge for data synchronization.

If you’re using an ERP system with built-in connectors for procurement tools, leverage them to reduce customization efforts. Consider the cost, scalability, and maintenance requirements of each method before choosing. It’s also important to assess data security and compliance when exchanging sensitive procurement data.

Step 4: Prepare Data and Standardize Processes

Data quality is a critical success factor in ERP integration. Clean and structure your procurement data to match ERP formatting requirements. Remove duplicates, outdated vendor records, and inconsistent entries. Any discrepancies in master data, such as supplier names or item codes, can result in system errors or failed transactions.

Standardize procurement workflows and approval chains across departments. This ensures the integrated system can process transactions uniformly, minimizing exceptions and errors. Process documentation and user role definition are key tasks in this step.

Step 5: Develop and Deploy the Integration

With systems evaluated and goals defined, development can begin. Whether you’re working with internal IT teams or external vendors, use an agile development approach. Start with a small integration module and expand incrementally.

Set up regular checkpoints to ensure the integration aligns with defined goals. Test individual modules for functionality, security, and performance before full-scale deployment. Proper documentation at this stage will support future updates or expansions.

Step 6: Test, Train, and Optimize

Before going live, conduct end-to-end testing with real procurement data. Identify and fix any errors in data synchronization, approval routing, or reporting functions. Pilot programs involving a small user group can help detect usability issues early.

Train users extensively on the new integrated workflow. Provide user guides, videos, and live support during the early days of the rollout. Once deployed, monitor key performance indicators such as order accuracy, procurement cycle time, and user satisfaction.

Use this feedback to fine-tune the system. ERP and supply chain integration is an ongoing process that evolves with your business needs.

Read more: ERP Procurement: Optimize ERP System Purchasing with Clear Steps & Roles

5. AgileTech’s Procurement System – Ready for ERP Integration

The system is built to accommodate evolving procurement needs and compliance requirements, ensuring your ERP integration remains future-proof. AgileTech’s platform is customizable, allowing organizations to tailor dashboards, approval workflows, and reporting features without heavy coding.

AgileTech also provides consulting and post-deployment optimization services, helping companies adapt their procurement workflows as they scale. Our clients benefit from ongoing system enhancements, robust documentation, and fast issue resolution, ensuring smooth alignment between ERP and supply chain operations.

If you’re looking for a procurement solution that integrates seamlessly with ERP systems, AgileTech offers a robust and scalable platform tailored to your needs. Designed for fast-growing enterprises, AgileTech’s Procurement System features real-time analytics, automated workflows, and intelligent vendor management that strengthen ERP supply chain software performance.

Whether you’re using SAP, Oracle, Microsoft Dynamics, or a custom ERP tool, our solution supports flexible ERP integration using modern API architecture. AgileTech ensures smooth synchronization between procurement processes and core ERP modules like inventory, finance, and supply chain management ERP software.

Our implementation team supports you at every step, from system analysis to deployment and optimization. By choosing AgileTech, you gain a reliable partner in enhancing your procurement-to-pay process and unlocking the full capabilities of your ERP supply chain software.

6. Conclusion

Integrating your procurement system with ERP is no longer optional in today’s competitive environment. It is a strategic move that improves operational transparency, reduces inefficiencies, and aligns procurement with business goals.

With the right supply chain management ERP software and a clear integration roadmap, companies can unlock a new level of procurement excellence. Don’t wait for inefficiencies to affect your bottom line. Invest in a well-integrated system that supports long-term growth and supply chain resilience.

For a future-ready solution that delivers measurable results, consider AgileTech’s Procurement System – designed to power smart, scalable ERP integration.