Inventory Management Software Cost in 2025: What You Should Know

Inventory management software cost in 2025 depends on several key factors: the type of software, your business size, and the features you need. While some systems start at just a few thousand dollars, enterprise-level solutions can reach hundreds of thousands. This article provides a complete cost breakdown to help you plan smart and invest wisely.

1. Key Factors That Influence Inventory Management Software Cost

1.1. Type of Software: SaaS, On-Premise, or Custom

Custom inventory management software is especially valuable for companies in retail, eCommerce, and distribution that require tailored tools to manage warehouse operations and supply chain processes internally. These systems are developed to meet highly specific business requirements, integrate with existing internal systems, and support unique workflows that off-the-shelf products often cannot accommodate.

For example, a logistics SaaS startup partnered with the team to build a custom inventory platform that could track multi-warehouse stock movements in real-time. By leveraging a modular architecture, they launched a scalable system that began as a $40,000 MVP and expanded to a $180,000 solution over two years, tailored to their clients’ needs in the freight forwarding industry.

1.2. Number of Users and Warehouses

As businesses grow in scale and distribution, managing multiple users and warehouses becomes increasingly complex. Inventory systems must adapt to distributed teams, location-specific workflows, and high volumes of simultaneous transactions.

The scale of the intended end-use significantly affects software complexity. The more users and warehouse locations the software must support, the more robust the system needs to be. Development time, testing, and configuration increase accordingly. The team helps service providers define a modular backend that accommodates various user tiers and distributed warehouse structures. They also ensure that performance remains consistent regardless of system load through cloud-native architecture and scalable APIs.

Take, for instance, a wholesale distributor with over 20 warehouse locations and 300 daily system users. They required inventory visibility across all nodes with support for user-specific access control. The team designed a system that supported region-based permissions, customized workflows per warehouse, and a mobile app extension for on-site staff, all under a $130,000 development budget.

1.3. Feature Set and Integration Requirements

Advanced inventory software often requires integration with ERP systems, accounting software, and customer-facing platforms. Features such as automated replenishment, barcode scanning, and predictive analytics increase complexity. These require skilled planning, architecture, and implementation, which the team handles as part of its end-to-end service. They evaluate the feasibility and ROI of each feature and offer suggestions for phased rollouts to balance functionality and cost.

For example, one of the partners needed real-time synchronization between their inventory software and a third-party eCommerce solution. The team developed a middleware connector and implemented a logic that allowed inventory counts to update within 30 seconds of any sale, resulting in reduced order errors and saving an estimated $15,000 per quarter in lost sales.

Read more: How to Build a Software Inventory Management System: Key Features, Costs, and Development Guide

2. Average Cost by Project Complexity

Cost structures vary significantly depending on the complexity of the software solution being developed. Inventory software projects generally fall into three main tiers: basic, mid-level, and enterprise-grade systems. These tiers differ in price, scale, features, and long-term maintenance requirements. Below is a deeper look at what defines each level.

2.1. Basic Inventory Software: Starting from $5,000

The cost of developing basic inventory software largely depends on the client’s requirements, the specific feature set included, and the technologies used. Typical requests from clients at this level include core functionalities such as product entry, quantity adjustments, basic stock alerts, and sales tracking. If the client requires additional features like mobile access, offline mode, or integration with accounting tools, costs can increase.

From a technology perspective, companies typically use lightweight front-end frameworks like React or Vue.js and back-end stacks such as Node.js or Laravel. For databases, Firebase or MySQL are often sufficient to handle real-time updates without the complexity of enterprise tools. Open-source libraries and prebuilt UI components can also help reduce development hours.

Costs may also be influenced by the extent of UI/UX customization, the need for multilingual support, and data security requirements. Clients operating in regulated industries, even on a small scale, may require extra compliance layers that affect scope and cost.

For example, in the food service sector, a catering company used a $6,500 inventory system to manage perishables, automatically calculate usage rates, and alert staff to nearing expiration dates, cutting waste by 18% in three months. Similarly, a small construction firm opted for a $7,200 solution that tracked material consumption across four job sites. The result: 22% fewer redundant purchases and better coordination with vendors.

In these cases, the final cost depends not only on the number of features but also on the business’s internal processes, the customization needed, and whether mobile support or third-party integrations are required.

2.2. Mid-Level Solutions: $25,000–$100,000

Costs for mid-level inventory systems depend on the scale of operations, the number of users, and the level of process automation the client expects. Clients often request real-time syncing across multiple warehouses, predictive restocking, purchase order automation, and customizable reporting.

Technically, these systems are built with scalable infrastructure such as containerized microservices and real-time messaging queues like RabbitMQ or Kafka. API integrations are essential and may connect with third-party CRM, ERP, or eCommerce systems. Companies also apply modular backend structures, often using Python (Django/FastAPI), Java, or .NET.

Cost is impacted by factors like data migration complexity, integration depth, and testing across different environments. For example, if a client requires bi-directional sync between inventory software and a cloud ERP or support for offline mobile warehouse apps, the scope and timeline grow significantly.

2.3. Enterprise Systems: $150,000 and Up

Enterprise solutions are highly customized to match complex operational needs. The cost is determined by client-specific requirements such as support for thousands of SKUs, advanced analytics dashboards, AI-driven forecasting, and compliance automation.

Clients typically require integration across multiple business units, regulatory adherence, detailed permission hierarchies, and SLA-based uptime commitments. Functional demands include real-time dashboards, automated warehouse routing, international stock localization, and IoT device support.

Technology stacks used often include Kubernetes-based deployment on AWS/GCP, backend frameworks like Spring Boot or Django, AI toolkits such as TensorFlow or Azure AI, and robust logging systems. These projects demand multi-phase delivery cycles, large QA and DevOps involvement, and long-term service contracts.

Costs increase significantly when projects involve cross-border compliance (e.g., GDPR, HIPAA), multilingual deployment, or integration with legacy internal platforms. Each enterprise system becomes a living product, continuously evolving based on business expansion and operational data feedback.

For example, a global auto parts distributor required a fully custom inventory engine integrated with supplier performance dashboards, predictive demand AI, and compliance tracking. The team’s 18-month engagement, valued at $480,000, replaced five fragmented systems with one unified platform, leading to $1.1M in annual savings through improved stock accuracy and vendor accountability.

These projects require advanced planning, QA automation, disaster recovery setups, and performance benchmarking. Dedicated support teams are essential to monitor operations, provide SLA-backed maintenance, and coordinate upgrades across international divisions.

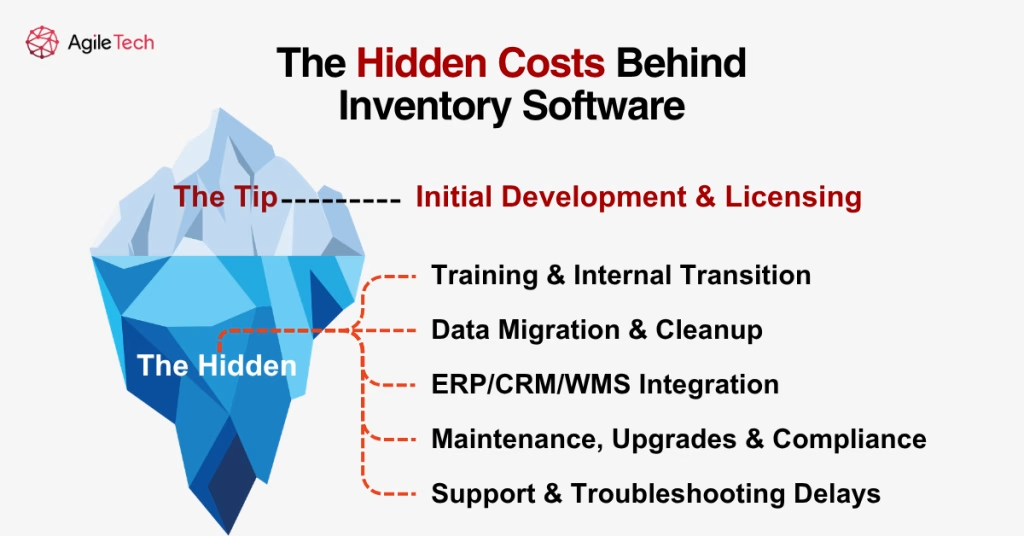

3. Hidden Costs to Consider

While upfront costs are often well-defined, many projects experience budget strain due to unforeseen or underestimated expenses. Identifying and planning for these hidden costs is critical. These costs typically arise during implementation, scaling, or long-term operation, and if not accounted for, can push total expenses beyond planned budgets.

Hidden costs also vary by industry. In retail, seasonal hiring may require additional user licenses and training resources. In manufacturing, integration with legacy equipment or old warehouse systems may lead to costly customizations. In healthcare and pharmaceuticals, compliance with data privacy regulations (like HIPAA or GDPR) could demand extra security layers, audits, or documentation not initially scoped.

3.1. Employee Training and Internal Transition

Training is one of the most underestimated costs in system rollouts. Even with an intuitive interface, users require onboarding to understand workflows, reduce resistance to change, and avoid operational errors. For mid-sized companies, training may involve dozens or even hundreds of staff, and each misstep could result in inventory discrepancies or slowdowns.

One food processing company with multiple locations underestimated this cost and initially delayed formal training. They experienced a 30% drop in order accuracy during the first two weeks post-launch. By implementing a structured, video-based training suite and guided walkthroughs from the development team, they reversed the trend within three weeks.

Clients that include learning tools early, such as embedded LMS features or self-paced training portals, typically experience 40–60% faster adoption rates and reduced long-term support needs.

3.2. Integration with ERP, CRM, or WMS

Connecting new inventory platforms with other systems, especially ERP or CRM software, is essential for workflow continuity but often underestimated in terms of time and cost. Legacy systems may lack modern APIs, forcing teams to develop workarounds or manual syncing processes.

For example, an electronics distributor needed to integrate a custom-built inventory system with their existing SAP ERP. The initial plan budgeted 80 hours for integration, but outdated infrastructure and undocumented API endpoints pushed the requirement to over 160 hours. The team helped reduce this by creating middleware and building reusable templates that were used in three subsequent integration rollouts.

Planning with full data mapping and API audits before implementation can reduce surprises and save thousands of dollars in rework.

3.3. Data Migration, Updates, and Maintenance

Bringing historical data into a new system is rarely a plug-and-play process. Older records often contain inconsistencies, formatting errors, or duplications. Each needs cleansing, transformation, and validation before the data is usable. In high-volume environments, this process can add significant time and cost.

A wholesale distributor migrating 10 years of data across five warehouses encountered over 4,000 duplicated records and inconsistent item naming. The team deployed a custom data audit tool and worked with internal IT to define rule-based cleansing logic, cutting the migration timeline by 30%.

After go-live, ongoing updates and system maintenance can also incur costs. Without proactive monitoring and version control, teams risk software becoming outdated or incompatible. Establishing long-term support agreements that include performance checks, patching schedules, and security audits can save up to 25% in unexpected downtime costs over a 3-year period.

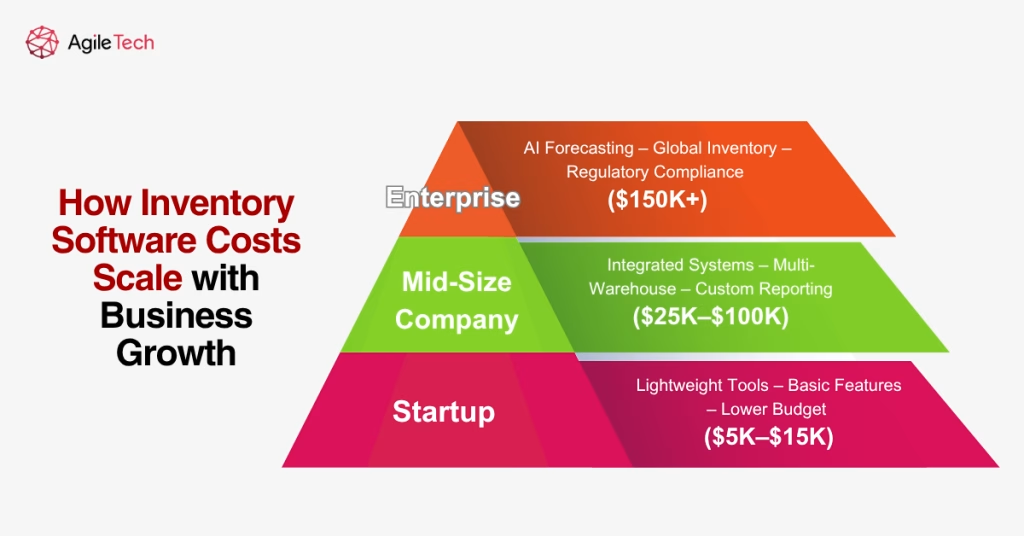

4. Cost by Business Size and Needs

Choosing the right inventory management system means aligning features, infrastructure, and development strategy with the company’s growth stage and digital maturity. This section explores the key cost factors and technology stack considerations for businesses building custom inventory software from scratch, particularly in industries like retail, e-commerce, wholesale, and logistics.

4.1. For Small Businesses and Startups

Startups and small retail chains often need lightweight, user-friendly systems that eliminate manual tracking and improve day-to-day visibility. Common requirements include basic item-level tracking, barcode generation, and low-stock alerts. Pricing typically ranges from $5,000–$15,000.

From a technology standpoint, these projects tend to leverage open-source stacks and cloud-native databases like Firebase or Supabase. Frontend frameworks such as React or Vue.js, combined with lightweight backends (e.g., Node.js or Laravel), ensure fast development and responsive interfaces. Mobile-first design and offline functionality are often prioritized for flexibility.

For example, a coffee roastery with three locations implemented a system for $7,800 with mobile support and automated reorder alerts. They reduced shrinkage by 22% and saw a full ROI in just five months.

4.2. For Growing Mid-Size Companies

As mid-sized businesses expand, so do their software demands. In addition to syncing inventory across multiple locations, clients often request role-based access, supplier integration, fulfillment status tracking, and reporting dashboards. Pricing generally falls between $25,000 and $100,000.

These systems commonly rely on containerized microservices, scalable APIs (using REST or GraphQL), and integrations with CRM or ERP systems. Backend frameworks like Django or ASP.NET Core are frequently used, along with PostgreSQL or MongoDB for complex queries and fast indexing. Middleware helps link to platforms like Shopify, WooCommerce, or internal warehouse tools.

One retail apparel brand scaled from four to nine stores and invested $60,000 in a tailored platform with multi-channel sync, vendor automation, and advanced sales analytics. Reordering time was cut in half, and inventory variance dropped by 19%.

4.3. For Large Enterprises with Complex Supply Chains

Enterprises typically operate across regions or continents and require robust inventory platforms with real-time analytics, AI-driven insights, and granular control over workflows. Functional expectations include warehouse-to-store transfers, automated purchasing decisions, IoT integrations, and compliance modules. Projects start at $150,000 and can exceed $1M.

Popular technologies include Kubernetes-managed environments on AWS/GCP, AI libraries like TensorFlow, and big data tools (e.g., Apache Spark) for forecasting. Data security, disaster recovery, multilingual support, and API orchestration through platforms like Mulesoft or Apache Camel are also critical.

A logistics enterprise with five regional hubs implemented a multilingual system with predictive inventory, demand forecasting, and IoT warehouse sensors. Developed over 18 months for $480,000, it replaced siloed systems and delivered $1.5M in annual operational savings.

Read more: How to create an inventory management software: From Spreadsheets to Software

5. How AgileTech Helps Optimize Inventory Software Costs

The real value in controlling inventory software costs doesn’t come from slashing features; it comes from smart planning, flexible execution, and sustained post-launch support. AgileTech applies a consultative, long-term approach in every engagement, ensuring each solution is tailored to the client’s operational model and scalable for future needs. Here’s how AgileTech delivers on this promise across three critical dimensions.

5.1. Modular, Scalable Development Approach

AgileTech builds inventory platforms with a modular architecture to ensure flexibility and cost-efficiency. Each component, such as SKU tracking, analytics, or supplier integration, is built, tested, and deployed independently. This structure enables clients to prioritize urgent features and scale the platform gradually, reducing waste and technical debt.

For example, a regional distributor began with a simple warehouse dashboard to track SKU movement across two locations. Six months later, they added barcode scanning and automated procurement modules, all without rebuilding the core system. This pay-as-you-scale approach helped them avoid $30,000 in upfront costs and adapt the platform to their actual operational complexity over time.

5.2. Focus on Cost Efficiency and Business Fit

AgileTech begins each project with in-depth discovery workshops to define the smallest viable product that meets real business goals. This prevents overbuilding and ensures that resources are invested where they matter most. AgileTech also provides iterative design, prototyping, and measurable KPIs to track ROI from the earliest stages.

One retail supply chain operator partnered with AgileTech to digitize their inventory processes. By launching a simplified system focused on stock syncing and vendor reporting while deferring AI forecasting to a later phase, they cut unnecessary spending and saw $50,000 in operational savings within the first year.

5.3. Industry-Specific Consulting and Support

AgileTech tailors each solution based on industry-specific workflows, regulations, and customer expectations. Whether serving retail, logistics, or pharmaceutical clients, AgileTech provides strategy-first consultation and technical design aligned with the company’s unique structure.

In the pharmaceutical sector, AgileTech developed a batch-level inventory system with compliance reporting and expiry alerts. For a retail chain, AgileTech built features that adjust product visibility and reorder logic during peak seasons. These examples reflect AgileTech’s ability to map software logic to real-world operations.

AgileTech’s post-launch services include SLA-based maintenance, proactive monitoring, security updates, and access to emerging technologies like AI forecasting or IoT-enabled tracking. This end-to-end partnership ensures that every platform remains optimized, secure, and future-ready.

6. Conclusion

Inventory management software cost in 2025 varies by system type, feature requirements, and business size. Startups benefit from lightweight tools, mid-sized firms require scalable systems, and enterprises need fully customized platforms.

By combining technical depth, industry insight, and modular development, AgileTech helps companies in logistics, retail, and eCommerce build inventory platforms tailored to their needs, efficient, scalable, and built to support long-term growth.

Looking ahead, companies investing in adaptive and well-integrated inventory systems will be better positioned to respond to global supply chain challenges, automation demands, and customer expectations.

AgileTech supports businesses in this journey by offering tailored software development services that fit each company’s structure, goals, and operational model. Whether you are a SaaS provider, a supply chain integrator, or a consulting firm helping clients digitize logistics, AgileTech brings experience and technical precision to every step of the process.

Ready to deliver a powerful, future-ready inventory system? Get in touch with AgileTech today to explore a solution that scales with your success.