How to Build a Software Inventory Management System: Key Features, Costs, and Development Guide

In today’s fast-paced business environment, manual tracking is no longer enough. Companies across industries are turning to inventory management software development to streamline operations, reduce waste, and improve supply chain visibility. Whether you’re managing retail stock, warehouse logistics, or production materials, investing in a tailored software inventory management system can transform how you operate.

This guide explores everything you need to know to build a powerful inventory programming solution—from choosing the right tech stack to identifying must-have features and estimating development costs. Whether you’re planning to upgrade your existing software inventory or launch a fully custom managed inventory software solution, this article will help you plan effectively and stay ahead of the competition.

- 1. Introduction

- 2. Types of Inventory Management Systems

- 3. Core Features of Inventory Management Software

- 5. Inventory Management Software Development Process

- 6. Trending 2025 Technologies in Inventory Management Software Development

- 7. Cost to Build an Inventory Management System

- 8. How to Choose a Reliable Inventory Software Development Partner

- Conclusion

1. Introduction

What is inventory management software?

Inventory management software is a digital tool that helps organizations monitor, control, and optimize stock levels throughout the supply chain. These platforms enable businesses to track inventory movement, generate reports, forecast demand, and automate replenishment processes. Whether deployed on-premise or in the cloud, a well-designed software inventory management system provides end-to-end visibility and operational control.

Why businesses need it today

In the current business landscape, companies face rising customer expectations, supply chain disruptions, and shrinking margins. Manual methods like spreadsheets or outdated systems can’t keep up with the complexity and scale of modern operations. By investing in manage inventory software, businesses can eliminate stock inaccuracies, reduce carrying costs, prevent overstocking or understocking, and streamline order fulfillment.

Furthermore, automation through inventory programming minimizes human error and enables instant data access across departments. This not only saves time but also ensures more accurate business decisions. For businesses expanding across multiple locations or managing thousands of SKUs, robust software inventory solutions become critical to maintaining agility and competitiveness.

Market demand and industries that benefit the most

The rising complexity of supply chains and growing pressure for operational efficiency are fueling the demand for inventory management software development. Companies need more than just spreadsheets—they require intelligent, automated systems to track, control, and optimize inventory in real time.

Retailers depend on manage inventory software to maintain stock accuracy across physical stores and eCommerce channels, preventing overstock and out-of-stock issues. In manufacturing, inventory programming helps align production cycles with material availability, reducing downtime and minimizing waste.

In the healthcare sector, software inventory systems are essential for tracking medical supplies and pharmaceuticals, where accuracy directly impacts patient safety. Logistics and warehousing businesses use software inventory management systems to manage multi-location storage, automate fulfillment, and increase delivery speed.

Even industries like food and beverage benefit from custom inventory solutions, especially when tracking expiration dates and ensuring regulatory compliance. These growing needs highlight why more organizations are moving from generic tools to tailored inventory management software—built to match their specific workflows and scale with business growth.

2. Types of Inventory Management Systems

Based on Business Size

Basic inventory systems are typically built for small businesses or startups. These systems focus on core features like manual stock input, low stock alerts, and basic reporting. For companies just starting to digitize operations, these lightweight software inventory tools can improve visibility without overwhelming users with advanced functionality. They are cost-effective and easy to deploy, making them ideal for businesses with low transaction volumes and limited product catalogs.

On the other end of the spectrum, enterprise inventory software is designed for large-scale businesses with complex logistics and multiple locations. These platforms are far more advanced, supporting automation, detailed analytics, integration with ERP/CRM systems, and demand forecasting. Enterprise-grade software inventory management systems are built to handle high transaction volumes, diverse product lines, and intricate workflows, offering deep customization to align with strategic goals.

Based on Deployment

When it comes to deployment, businesses can choose from on-premise, cloud-based, or hybrid inventory systems. On-premise solutions are installed directly on a company’s servers. They provide full control over data and infrastructure but typically involve higher upfront investment and IT maintenance. These systems are suitable for organizations with strict data security requirements or limited internet connectivity.

In contrast, cloud-based inventory software is hosted on remote servers, providing users with anytime, anywhere access. This model supports scalability, reduces infrastructure costs, and allows for easier updates and integrations—making it a preferred option in modern inventory programming. It’s especially effective for companies with remote teams, distributed warehouses, or dynamic supply chains.

Hybrid solutions combine the benefits of both on-premise and cloud systems. They offer flexible deployment, allowing sensitive data to remain in-house while taking advantage of cloud scalability for other operations. This setup works well for enterprises that need both security and real-time collaboration.

By Inventory Model

Another key distinction lies in the inventory tracking model: perpetual vs. periodic systems. A perpetual inventory system continuously updates stock levels in real-time using barcodes, RFID, or IoT sensors. It provides a live view of inventory across all locations, which is critical for fast-paced environments such as retail, logistics, or e-commerce. These systems allow for better decision-making, reduce shrinkage, and enhance supply chain responsiveness through real-time software inventory updates.

On the other hand, a periodic inventory system records inventory at fixed intervals, such as weekly or monthly. It’s easier to implement and less costly, making it a viable option for smaller businesses or those with less frequent stock movement. However, it lacks real-time data and may lead to delays in identifying stock discrepancies or shortages.

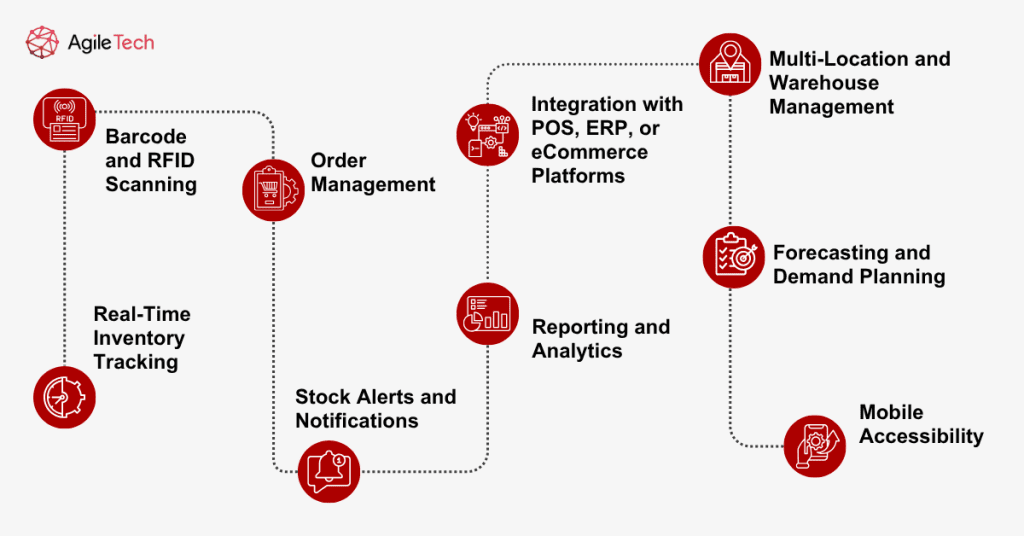

3. Core Features of Inventory Management Software

When investing in inventory management software development, understanding the core features is crucial. These features form the foundation of a functional and scalable system that enables businesses to operate efficiently and respond to market demands in real time. Whether you’re building a custom software inventory management system or refining an existing one, the following capabilities are essential.

Real-Time Inventory Tracking

At the heart of every modern manage inventory software is real-time tracking. This feature ensures that inventory data is constantly updated across all channels—physical stores, warehouses, or eCommerce platforms. It helps businesses avoid discrepancies, prevent stockouts, and keep inventory levels optimized. For industries with fast-moving goods, real-time tracking enables accurate decision-making and improved customer satisfaction.

Barcode and RFID Scanning

Barcode and RFID (Radio-Frequency Identification) integration allow for quick and accurate inventory input. These technologies reduce manual errors by automating data capture during stock receipt, transfer, and shipping. Barcode scanning is widely used in retail and warehousing, while RFID tags offer greater tracking range and are ideal for high-value or fast-moving inventory. This feature supports seamless inventory programming for faster and more secure operations.

Order Management

A robust software inventory platform must streamline the entire order lifecycle—from procurement to fulfillment. This includes managing purchase orders, backorders, supplier relationships, and delivery tracking. Integrated order management ensures that customer expectations are met without overburdening internal teams or causing delays in restocking critical items.

Stock Alerts and Notifications

Proactive stock alerts help prevent disruptions by notifying users when inventory reaches minimum thresholds or when items are running low. Automated notifications can be customized based on product category, demand frequency, or seasonal trends. This feature reduces the risk of stockouts or overstocking, making manage inventory software more responsive and efficient.

Reporting and Analytics

Detailed reports and dashboards provide actionable insights into inventory turnover, carrying costs, supplier performance, and demand trends. These analytics support data-driven decision-making and strategic planning. Whether you’re looking to cut costs, increase efficiency, or prepare for seasonal shifts, real-time reporting is a must-have in any software inventory management system.

Integration with POS, ERP, or eCommerce Platforms

A modern inventory management software solution should seamlessly integrate with point-of-sale (POS) systems, enterprise resource planning (ERP) software, and eCommerce platforms. These integrations enable unified data flow across departments, improve sales forecasting, and automate inventory updates. For example, a sale processed at the POS should instantly reflect in your stock records and trigger reordering if necessary.

Multi-Location and Warehouse Management

For businesses operating across multiple warehouses or store locations, centralized inventory control is critical. Multi-location support allows users to track stock transfers, manage location-specific thresholds, and compare warehouse performance. This capability ensures consistency across your supply chain and simplifies operations, especially for global businesses.

Forecasting and Demand Planning

Predictive analytics and AI-driven forecasting enable businesses to anticipate demand fluctuations and adjust inventory accordingly. By analyzing historical sales data, market trends, and seasonal behavior, inventory programming can help companies maintain the right stock levels, reduce excess inventory, and optimize procurement planning.

Mobile Accessibility

In an increasingly mobile world, having access to your software inventory on the go is essential. Mobile-friendly inventory solutions allow warehouse managers, field staff, and decision-makers to perform key actions—from scanning items to checking stock levels—using smartphones or tablets. Mobile accessibility increases flexibility, improves response time, and enhances overall inventory control.

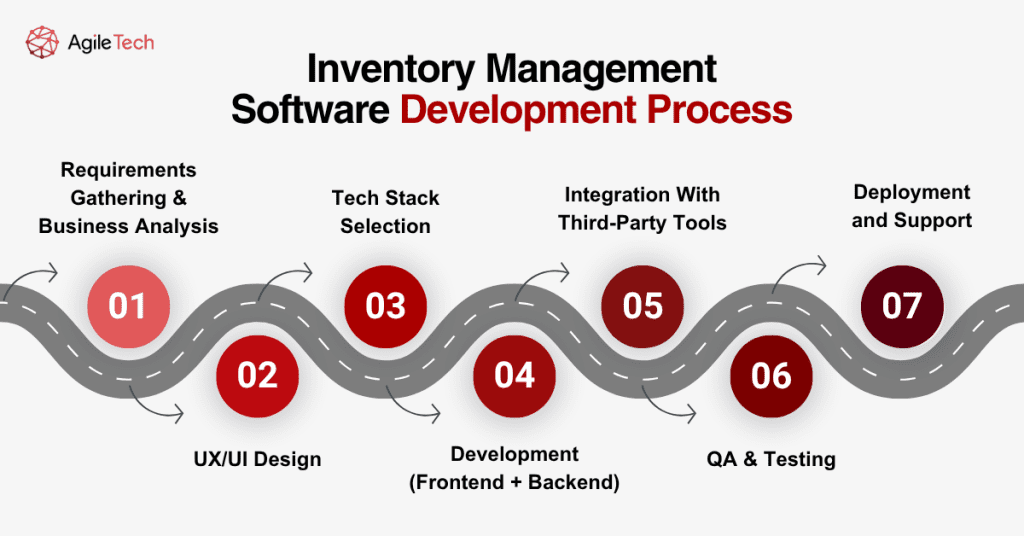

5. Inventory Management Software Development Process

Developing a high-performing inventory management software solution involves a structured, step-by-step process that ensures both functionality and scalability. Whether you’re building a basic tool for internal use or a full-fledged enterprise platform, following a clear development roadmap helps align business goals with technical execution.

Step 1: Requirements Gathering & Business Analysis

The first stage of inventory management software development begins with understanding your business needs, challenges, and workflows. Developers and product teams work closely with stakeholders to define the software’s scope, target users, inventory models (e.g., perpetual vs. periodic), and integration needs. This phase helps identify pain points such as inventory mismatches, fulfillment delays, or reporting limitations. Clear documentation of requirements ensures that the resulting manage inventory software meets both current and future needs.

Step 2: UX/UI Design

Once the requirements are finalized, the next step is creating intuitive and user-friendly interfaces. The UX/UI design phase focuses on mapping out how users will interact with the system, from adding new products to tracking warehouse movements. Designers develop wireframes, prototypes, and user journeys to visualize how the software inventory management system will look and feel. The goal is to ensure that the interface is clean, functional, and tailored to different user roles, such as warehouse staff, inventory managers, and executives.

Step 3: Tech Stack Selection

Choosing the right technologies is critical to building a stable and scalable system. The development team selects a suitable tech stack based on the software’s complexity, performance needs, and deployment model (on-premise, cloud, or hybrid). For example, React or Angular may be chosen for the front end, while Node.js, Python, or .NET might power the backend. Databases like PostgreSQL or MongoDB are common for storing software inventory records. Cloud services such as AWS or Google Cloud may be used for hosting and scalability.

Step 4: Development (Frontend + Backend)

With the tech stack in place, the actual inventory programming begins. The frontend team builds the user interface and client-side logic, ensuring a responsive experience across devices. The backend team focuses on server-side development, implementing features such as real-time tracking, data processing, role-based access, and business logic. Development is typically done in sprints using Agile methodology, allowing for iterative improvements and ongoing feedback from stakeholders.

Step 5: Integration With Third-Party Tools

To maximize functionality, custom inventory management software often needs to integrate with existing business tools. This may include connecting the system to ERP, CRM, POS, eCommerce platforms, payment gateways, or accounting software. These integrations ensure seamless data exchange and eliminate the need for manual data entry. APIs (Application Programming Interfaces) are commonly used to facilitate secure and efficient communication between systems.

Step 6: QA & Testing

Before launch, thorough testing is essential to ensure the software inventory management system works as expected. QA engineers conduct various tests, including functional, usability, performance, and security testing to identify and resolve bugs. Load testing is especially important for systems handling large transaction volumes or operating across multiple locations. This step ensures that users have a reliable and secure experience post-deployment.

Step 7: Deployment and Support

Once the system passes all tests, it is deployed to the production environment. For cloud-based manage inventory software, this may involve deploying the solution to platforms like AWS or Azure. For on-premise models, it includes configuring servers and ensuring infrastructure readiness. Post-launch support is equally important developers provide updates, monitor performance, and address user feedback. Ongoing maintenance ensures the software remains aligned with evolving business needs and industry standards.

6. Trending 2025 Technologies in Inventory Management Software Development

AI and Machine Learning (ML) for Predictive Inventory Optimization

Artificial Intelligence and Machine Learning are playing a central role in modern inventory programming. AI-powered algorithms analyze massive amounts of inventory data—sales trends, supplier performance, seasonal fluctuations—to forecast future demand with high accuracy. This enables dynamic stock level adjustments, automatic reordering, and reduced holding costs. For example, retailers can avoid stockouts during peak seasons, while manufacturers can optimize raw material procurement in real time. ML continuously learns from new data, ensuring that your managed inventory software adapts to changing market behavior over time.

Business Intelligence (BI) and Advanced Analytics

Business Intelligence tools are transforming how companies visualize and act on their inventory data. Embedded BI dashboards within inventory management software provide managers with key performance indicators (KPIs), including inventory turnover ratio, order accuracy, and supplier lead times. With these insights, companies can make faster, data-backed decisions—such as phasing out slow-moving products or identifying operational bottlenecks. In 2025, BI integration has become a must-have, offering real-time reports, customized visualizations, and exportable analytics that support continuous process improvement.

Internet of Things (IoT) for Real-Time Inventory Tracking

IoT integration is revolutionizing how physical inventory is monitored. Smart sensors, RFID tags, GPS devices, and automated scanners provide continuous feedback about stock levels, movement, and storage conditions. For industries like food and pharmaceuticals, IoT devices ensure that products are kept at optimal temperature and humidity levels throughout the supply chain. When integrated into a custom software inventory management system, IoT can trigger alerts, automate stock updates, and support regulatory compliance—all while improving warehouse efficiency.

Cloud-Based Architecture and Mobility

With remote operations becoming standard, cloud-based inventory management software is now the default choice for scalability, flexibility, and cross-device access. Cloud solutions allow businesses to sync inventory across multiple warehouses and sales channels in real time. Coupled with mobile access, users can manage inventory on the go—performing audits, scanning items, or receiving alerts via smartphone or tablet. In 2025, businesses prioritize cloud-native platforms for their fast deployment, real-time collaboration, and cost-effective scalability.

API-First Ecosystems and Integration Flexibility

Modern inventory software is expected to integrate seamlessly with eCommerce platforms (Shopify, Magento), ERP systems (SAP, Oracle), and financial tools (QuickBooks, Xero). API-first development enables smooth data exchange between systems, reduces manual work, and ensures consistent inventory records across all departments. In 2025, inventory systems are being built with extensibility in mind—allowing businesses to plug in or swap out third-party services as they scale.

Voice and Chatbot Interfaces

Another rising trend in inventory management software development is the use of AI assistants or chatbots. These tools allow managers to request reports, check stock status, or update records through voice commands or chat interfaces. This improves accessibility, especially for frontline workers in warehouses who need quick access to data without navigating complex dashboards. As voice-enabled tech matures, it’s becoming an increasingly valuable feature for hands-free, real-time operations.

7. Cost to Build an Inventory Management System

The cost of inventory management software development depends on features, complexity, development approach, and team location. A basic manage inventory software solution with core features like tracking, stock alerts, and reporting typically ranges from $30,000 to $50,000.

For advanced systems with AI forecasting, IoT integration, multi-warehouse support, and third-party integrations, costs can reach $80,000–$150,000+, depending on scope. Development time ranges from 3 to 12 months, with MVPs taking less time than full-scale platforms.

In-house development offers more control but comes with higher long-term costs—best suited for large enterprises. Outsourcing, especially to experienced offshore teams, is more cost-effective and ideal for small to mid-sized businesses seeking quality and speed.

Though upfront costs can be high, custom-built software inventory management systems often deliver strong ROI through reduced errors, lower carrying costs, and streamlined operations.

8. How to Choose a Reliable Inventory Software Development Partner

Choosing the right development partner is critical to the success of your inventory management software development project. Beyond writing code, a reliable partner brings domain expertise, strategic thinking, and a commitment to building scalable, future-ready solutions tailored to your operations.

Experience and Portfolio

Start by assessing the partner’s past work. A company with a proven track record in building software inventory systems—especially for industries like retail, logistics, and manufacturing—will understand your operational challenges. At AgileTech, we’ve successfully delivered end-to-end inventory programming solutions for businesses across multiple sectors, helping them cut costs, eliminate errors, and optimize warehouse performance. You can explore our portfolio to see how we turn business requirements into real-world applications.

Industry Expertise

An experienced team familiar with your industry can offer insights that go beyond technical delivery. Whether you need advanced tracking for pharmaceuticals, demand forecasting for a manufacturing line, or smart stock syncing across sales channels, AgileTech brings deep knowledge of domain-specific needs. Our team aligns technical architecture with your workflows to ensure that your manage inventory software delivers real business value.

Communication and Project Management

Collaboration should be seamless. AgileTech uses Agile methodology to maintain transparency, reduce delivery risk, and adapt quickly to feedback. Our clients have access to dedicated project managers, clear timelines, and sprint-based reporting—ensuring that you always know where your project stands. No matter where you’re located, our global delivery model keeps communication responsive and effective.

Post-Launch Support

Launching your inventory management software is just the beginning. At AgileTech, we provide ongoing support, system monitoring, and continuous optimization to ensure your platform scales with your growth. From patch updates and system training to performance tuning, our long-term commitment gives you peace of mind.

Conclusion

Developing a custom inventory management system allows businesses to gain real-time visibility, reduce manual errors, and optimize stock control across the supply chain. By understanding the system types, core and advanced features, development process, and cost factors, organizations can make informed decisions that align with both operational needs and long-term goals. In a competitive landscape, investing in tailored, scalable inventory software is a key step toward greater efficiency and resilience.