Top 9 Inventory Management Software Features Every Business Should Know

Modern businesses require robust inventory management software features to maintain a competitive advantage. Understanding these critical capabilities ensures optimal stock control, reduced operational costs, and enhanced customer satisfaction across diverse industry sectors.

- 1. Functions of An Inventory Management System

- 2. Top 9 Key Features to Prioritize in an Inventory Management Software

- 3. How AI-Powered Tools Optimize Inventory Operations

- 4. Core Inventory Management System Features by Industry

- 5. How to Choose the Right Features for Your Tailored Inventory Management Software

- 6. Prepare for Long-term Success with Custom Inventory Management Software

1. Functions of An Inventory Management System

1.1. Core Operational Functions

An effective inventory management system serves as the backbone of modern business operations, orchestrating complex processes that extend far beyond simple stock counting. These systems integrate multiple operational functions to create a comprehensive framework for managing inventory throughout its entire lifecycle.

The primary function revolves around real-time inventory tracking, which provides businesses with accurate visibility into stock levels across multiple locations. This capability enables organizations to maintain optimal inventory levels while minimizing holding costs and preventing stockouts that could negatively impact customer relationships.

1.2. Data Integration and Analysis

Modern inventory management system software features encompass sophisticated data integration capabilities that connect with various business systems including enterprise resource planning platforms, customer relationship management tools, and accounting software. This integration creates a unified data ecosystem that eliminates information silos and provides comprehensive visibility into business operations.

The analytical functions within these systems transform raw inventory data into actionable insights. Advanced reporting capabilities enable businesses to identify trends, forecast demand patterns, and optimize purchasing decisions based on historical performance data and market conditions. Organizations considering custom solutions should explore comprehensive inventory management software development approaches that align with their specific operational requirements.

1.3. Automation and Workflow Management

Contemporary inventory management systems incorporate extensive automation features that streamline routine tasks and reduce human error. These automated workflows handle reorder point calculations, purchase order generation, and vendor communications without requiring manual intervention.

The workflow management capabilities extend to approval processes, where predetermined business rules govern purchasing decisions and inventory movements. This systematic approach ensures compliance with organizational policies while maintaining operational efficiency.

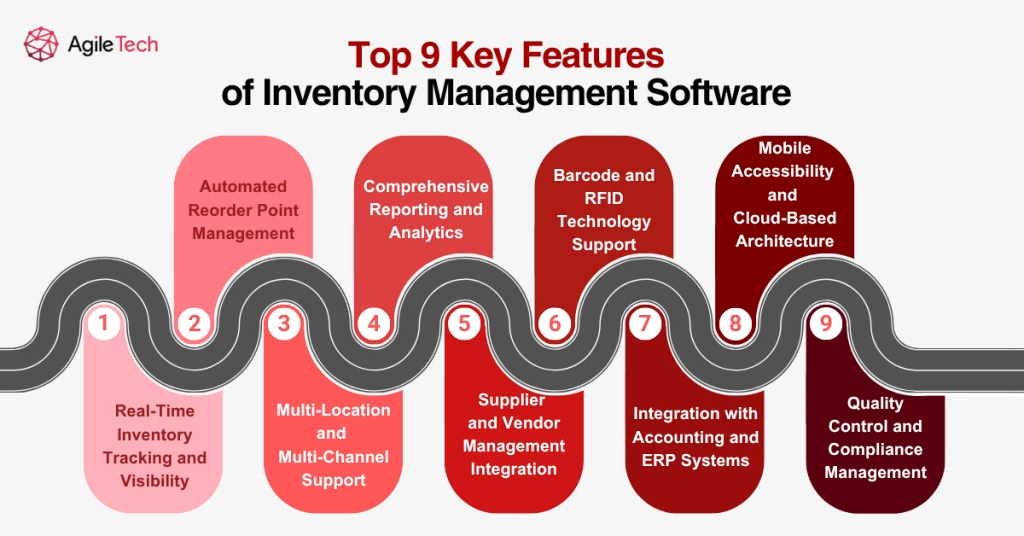

2. Top 9 Key Features to Prioritize in an Inventory Management Software

2.1. Real-Time Inventory Tracking and Visibility

Real-time inventory tracking represents the cornerstone of effective inventory management software features. This capability provides instantaneous updates on stock levels, location tracking, and inventory movements across all storage facilities and sales channels.

The visibility component extends beyond basic stock quantities to include detailed information about inventory conditions, expiration dates, and quality metrics. This comprehensive visibility enables businesses to make informed decisions about inventory allocation, product rotation, and quality control measures.

Advanced tracking systems utilize barcode scanning, RFID technology, and Internet of Things sensors to capture inventory data automatically. These technologies eliminate manual data entry errors while providing accurate, up-to-date information about inventory status and location.

2.2. Automated Reorder Point Management

Automated reorder point management eliminates the guesswork from inventory replenishment decisions. This feature calculates optimal reorder points based on historical consumption patterns, lead times, and safety stock requirements.

The system continuously monitors inventory levels and automatically triggers reorder alerts when stock reaches predetermined thresholds. This proactive approach prevents stockouts while avoiding excessive inventory holding costs.

Sophisticated algorithms within stock management software features consider seasonal variations, promotional activities, and market trends when calculating reorder points. This dynamic approach ensures that reorder thresholds remain relevant and effective across changing business conditions.

2.3. Multi-Location and Multi-Channel Support

Modern businesses operate across multiple locations and sales channels, requiring inventory management system features that support complex distribution networks. This capability enables centralized inventory management while maintaining location-specific control and reporting.

The multi-channel support extends to e-commerce platforms, retail stores, and wholesale operations, providing unified inventory visibility across all sales channels. This integration prevents overselling and ensures accurate inventory allocation across different customer touchpoints.

Advanced multi-location features include inter-location transfer management, location-specific pricing, and localized reporting capabilities. These functions enable businesses to optimize inventory distribution based on regional demand patterns and operational requirements.

2.4. Comprehensive Reporting and Analytics

Robust reporting and analytics capabilities transform inventory data into strategic business intelligence. These features provide detailed insights into inventory performance, cost analysis, and operational efficiency metrics.

The reporting functions include customizable dashboards that display key performance indicators relevant to different organizational roles. Management teams can access high-level strategic reports while operational staff receive detailed transaction-level information.

Advanced analytics features utilize machine learning algorithms to identify patterns, predict future demand, and recommend optimization strategies. These predictive capabilities enable businesses to make proactive decisions about inventory investments and operational improvements.

2.5. Supplier and Vendor Management Integration

Effective inventory management requires seamless integration with supplier and vendor management processes. This feature maintains comprehensive vendor profiles including performance metrics, pricing agreements, and delivery schedules.

The integration capabilities extend to automated purchase order generation, vendor communication, and receipt tracking. These functions streamline the procurement process while maintaining accurate records of all supplier interactions.

Advanced vendor management features include performance scorecards, contract management, and supplier relationship optimization tools. These capabilities help businesses maintain strong supplier relationships while ensuring competitive pricing and reliable delivery performance.

2.6. Barcode and RFID Technology Support

Modern inventory management software features incorporate advanced identification technologies, including barcode and RFID support. These technologies enable rapid, accurate data capture while reducing manual data entry requirements.

Barcode integration supports various symbologies and enables mobile scanning capabilities through smartphones and dedicated scanning devices. This flexibility allows businesses to implement cost-effective identification solutions without requiring significant infrastructure investments.

RFID technology provides enhanced tracking capabilities including bulk scanning, location tracking, and automated data capture. These advanced features enable businesses to achieve higher levels of inventory accuracy while reducing labor requirements.

2.7. Integration with Accounting and ERP Systems

Seamless integration with accounting and enterprise resource planning systems ensures accurate financial reporting and eliminates data synchronization issues. This integration automatically updates inventory valuations, cost of goods sold, and financial statements based on inventory transactions.

The ERP integration extends to manufacturing planning, customer relationship management, and human resources systems. This comprehensive integration creates a unified business system that eliminates information silos and improves operational efficiency.

Advanced integration capabilities include real-time data synchronization, automated journal entry generation, and comprehensive audit trails. These features ensure data consistency across all business systems while maintaining compliance with financial reporting requirements.

2.8. Mobile Accessibility and Cloud-Based Architecture

Mobile accessibility enables inventory management from any location using smartphones and tablets. This capability provides real-time inventory information to field personnel, sales teams, and management staff regardless of their physical location.

Cloud-based architecture offers scalability, reliability, and cost-effectiveness compared to traditional on-premises solutions. This deployment model eliminates the need for extensive IT infrastructure while providing automatic updates and maintenance.

The mobile and cloud capabilities include offline functionality, data synchronization, and security features that protect sensitive inventory information. These technical capabilities ensure reliable access to inventory data under various operational conditions.

2.9. Quality Control and Compliance Management

Quality control features enable businesses to maintain product quality standards throughout the inventory lifecycle. These capabilities include batch tracking, expiration date management, and quality inspection workflows.

Compliance management functions ensure adherence to industry regulations and internal quality standards. The system maintains detailed documentation of quality control activities and provides audit trails for regulatory compliance purposes.

Advanced quality control features include statistical process control, quality metrics tracking, and automated compliance reporting. These capabilities help businesses maintain consistent product quality while reducing compliance risks and associated costs.

3. How AI-Powered Tools Optimize Inventory Operations

Machine Learning for Demand Forecasting

Artificial intelligence transforms traditional inventory management through sophisticated machine learning algorithms that analyze vast amounts of historical data to predict future demand patterns. These AI-powered tools consider multiple variables including seasonal trends, market conditions, promotional activities, and external factors that influence product demand.

The machine learning capabilities continuously improve forecasting accuracy by learning from actual sales data and adjusting predictions based on performance feedback. This adaptive approach ensures that demand forecasts remain relevant and accurate as market conditions change.

Advanced AI algorithms can identify subtle patterns in customer behavior that traditional forecasting methods might miss. These insights enable businesses to anticipate demand fluctuations and adjust inventory levels proactively rather than reactively.

Predictive Analytics for Inventory Optimization

Predictive analytics capabilities within inventory management system software features utilize historical data and market trends to optimize inventory investments. These tools identify optimal stock levels that balance carrying costs with service level requirements.

The predictive models consider multiple factors including supplier lead times, demand variability, and cost implications when recommending inventory strategies. This comprehensive analysis ensures that inventory decisions align with overall business objectives and financial constraints.

AI-powered optimization tools can simulate various inventory scenarios and recommend strategies that maximize profitability while maintaining desired service levels. These capabilities enable businesses to make data-driven decisions about inventory investments and operational strategies.

Automated Decision Making and Process Optimization

AI-powered automation extends beyond simple rule-based decisions to include complex optimization problems that require sophisticated analysis. These systems can automatically adjust reorder points, optimize purchase quantities, and schedule inventory movements based on real-time conditions.

The automated decision-making capabilities consider multiple constraints and objectives simultaneously, finding optimal solutions that human operators might not identify. This systematic approach ensures consistent, objective decision-making that eliminates human bias and errors.

Advanced AI systems can learn from operational outcomes and continuously improve their decision-making algorithms. This self-improving capability ensures that automation benefits increase over time as the system gains experience with specific business conditions.

4. Core Inventory Management System Features by Industry

4.1. Manufacturing and Production Industries

Manufacturing organizations require specialized stock management software features that address the complexities of production planning, bill of materials management, and work-in-progress tracking. These industries benefit from advanced lot tracking capabilities that maintain detailed records of raw materials, components, and finished goods throughout the production process.

The manufacturing-specific features include capacity planning tools that coordinate inventory availability with production schedules. These capabilities ensure that raw materials and components are available when needed while minimizing work-in-progress inventory levels.

Quality control features become particularly important in manufacturing environments where product defects can result in significant costs and liability issues. Advanced quality management capabilities include statistical process control, inspection workflows, and non-conformance tracking.

4.2. Retail and E-commerce Sectors

Retail and e-commerce businesses require inventory management software features that support rapid inventory turnover, seasonal demand variations, and multiple sales channels. These organizations benefit from advanced category management tools that optimize product mix and merchandising strategies. Successful inventory management in e-commerce operations depends on real-time synchronization between online storefronts and inventory databases to maintain accurate product availability information.

The retail-specific capabilities include promotional planning features that coordinate marketing activities with inventory availability. These tools ensure that promotional campaigns are supported by adequate inventory levels while preventing excess stock accumulation.

Size, color, and style matrix management become crucial for fashion and apparel retailers. Advanced attribute management features enable detailed tracking of product variations while maintaining aggregate visibility for planning purposes.

4.3. Healthcare and Pharmaceutical Applications

Healthcare organizations require specialized inventory management system features that address regulatory compliance, expiration date management, and lot tracking requirements. These industries must maintain detailed records of product provenance and usage for regulatory auditing purposes.

The healthcare-specific features include controlled substance tracking capabilities that ensure compliance with regulatory requirements while preventing unauthorized access. These systems maintain detailed audit trails and access controls that protect sensitive inventory information.

Temperature and environmental monitoring capabilities become essential for pharmaceutical inventory management. Advanced environmental tracking features ensure that temperature-sensitive products are stored and transported under appropriate conditions.

4.4. Food and Beverage Industry Requirements

Food and beverage organizations require inventory management software features that address perishable inventory management, FIFO rotation, and food safety compliance. These industries must maintain detailed records of product freshness and implement strict rotation policies to prevent spoilage. Restaurant inventory management requires specialized features that address the unique challenges of food service operations, including recipe costing and waste tracking capabilities.

The food-specific capabilities include recipe and formula management features that track ingredient usage and calculate nutritional information. These tools ensure consistent product quality while managing complex ingredient inventories.

Traceability features become particularly important for food safety compliance. Advanced traceability capabilities enable rapid identification of affected products in case of contamination or recall situations.

5. How to Choose the Right Features for Your Tailored Inventory Management Software

5.1. Assessing Business Requirements and Objectives

The selection of appropriate inventory management software features begins with a comprehensive assessment of business requirements and strategic objectives. Organizations must evaluate their current inventory challenges, operational constraints, and growth projections to identify the most relevant capabilities. Before evaluating specific features, organizations should establish a clear understanding of what inventory management software is and how it aligns with their operational objectives.

This assessment process should involve stakeholders from various departments including operations, finance, sales, and information technology. Each department brings unique perspectives about inventory management requirements and system integration needs.

The requirements analysis should consider both current needs and future growth plans. Scalability becomes a crucial factor in feature selection, ensuring that the chosen system can accommodate business expansion without requiring complete replacement.

5.2. Evaluating Integration Capabilities and Technical Requirements

Technical integration capabilities represent a critical factor in selecting inventory management system software features. Organizations must evaluate how well potential systems integrate with existing business applications including accounting software, e-commerce platforms, and enterprise resource planning systems.

The integration assessment should consider both current system requirements and future technology plans. API availability, data format compatibility, and real-time synchronization capabilities become important technical considerations.

Security and compliance requirements must be evaluated carefully, particularly for organizations in regulated industries. The chosen system must provide appropriate security controls, audit trails, and compliance reporting capabilities.

5.3. Cost-Benefit Analysis and Return on Investment

A thorough cost-benefit analysis helps organizations select inventory management software features that provide the best return on investment. This analysis should consider both direct costs including software licensing and implementation expenses, and indirect benefits such as improved efficiency and reduced carrying costs.

The financial evaluation should include ongoing operational costs such as maintenance, training, and system administration. These recurring expenses can significantly impact the total cost of ownership over the system’s useful life.

Quantifiable benefits such as reduced inventory holding costs, improved order fulfillment rates, and decreased manual labor requirements should be included in the return on investment calculations. These measurable benefits help justify the investment and establish performance expectations.

5.4. Implementation Planning and Change Management

Successful implementation of new inventory management software features requires careful planning and change management strategies. Organizations must develop detailed implementation plans that address system configuration, data migration, and user training requirements.

The change management process should include communication strategies that help employees understand the benefits of new inventory management capabilities. Resistance to change represents a common challenge that must be addressed proactively through education and involvement.

Training programs should be developed to ensure that users can effectively utilize new stock management software features. These programs should include both initial training and ongoing support to address questions and challenges that arise during system usage. Organizations with unique requirements may need to understand how to create an inventory management software solution that addresses their specific operational challenges.

6. Prepare for Long-term Success with Custom Inventory Management Software

Plan for Scalability and Innovation

To support long-term growth, your inventory system must handle higher volumes, new locations, and more SKUs. Look for future-proof technologies like AI, IoT, and mobile capabilities that can evolve with your needs.

Commit to Ongoing Optimization

Regularly assess performance using key metrics and user feedback. Continuous training and system updates will help your team fully leverage available inventory management system software features.

Build Strategic Partnerships for Enhanced Capabilities

Collaborating with a trusted software partner like AgileTech ensures access to advanced features, tailored development, and responsive support. AgileTech works closely with businesses to align technology with strategic goals, offering long-term value through innovation and reliability.

Effective inventory management software features represent a critical investment in operational efficiency and competitive advantage. Organizations that carefully select and implement appropriate capabilities will be well-positioned to achieve sustainable growth while maintaining high levels of customer satisfaction. The key to success lies in understanding business requirements, evaluating available options thoroughly, and maintaining a commitment to continuous improvement and optimization.