Custom Inventory Software for Manufacturing Industry: Tech Stack, Benefits, and Expert Tips

Transform your manufacturing operations with custom inventory software solutions. Discover essential tech stack, implementation strategies, and benefits that streamline production workflows, reduce costs, and enhance operational efficiency for modern manufacturers.

- 1. Why Manufacturing Companies Need Custom Inventory Management Solutions

- 2. Technology Stack for Custom Manufacturing Inventory Solutions

- 3. Benefits of Using Custom Inventory Software in Manufacturing

- 4. Tips Before Implementing Custom Manufacturing Inventory Management Software

- 5. Choosing AgileTech for Tailored Manufacturing Inventory Tracking Software

1. Why Manufacturing Companies Need Custom Inventory Management Solutions

The Complexity of Modern Manufacturing Operations

Manufacturing companies face unprecedented challenges in today’s competitive landscape. The complexity of supply chains, diverse product lines, and increasing customer demands require sophisticated inventory management approaches that generic software solutions simply cannot address. Custom inventory software for the manufacturing industry provides the specialized functionality needed to handle these unique operational requirements.

Traditional inventory systems often fall short when applied to manufacturing environments. Understanding what inventory management software is fundamentally helps manufacturers recognize why generic solutions cannot address their complex operational requirements. These solutions typically lack the nuanced understanding of production workflows, bill of materials management, and the intricate relationships between raw materials, work-in-progress inventory, and finished goods. Manufacturing inventory management software must accommodate these complexities while providing real-time visibility across all operational levels.

Industry-Specific Challenges Requiring Specialized Solutions

Manufacturing companies encounter several critical challenges that demand tailored inventory management approaches. Production scheduling complexities arise when multiple product lines share common components, requiring sophisticated allocation algorithms that standard software cannot provide. Quality control integration becomes essential when inventory tracking must account for batch numbers, expiration dates, and compliance requirements specific to manufacturing standards.

Supply chain disruptions have become increasingly common, making demand forecasting and safety stock optimization more critical than ever. Manufacturing inventory tracking software must incorporate predictive analytics and machine learning capabilities to anticipate market fluctuations and adjust inventory levels accordingly. This level of sophistication requires custom development that understands the unique patterns and cycles within specific manufacturing sectors.

The Cost of Inadequate Inventory Management

Poor inventory management practices can devastate manufacturing operations through multiple channels. Excess inventory ties up valuable capital that could be invested in growth initiatives, while stockouts can halt production lines and damage customer relationships. Manufacturing companies using inadequate inventory systems frequently experience increased carrying costs, obsolescence risks, and inefficient resource allocation.

The ripple effects extend beyond financial metrics. Production delays caused by inventory shortages can cascade through entire supply chains, affecting customer satisfaction and market reputation. Custom inventory software for manufacturing company operations addresses these risks by providing precise control over inventory levels, automated reorder points, and integrated production planning capabilities.

2. Technology Stack for Custom Manufacturing Inventory Solutions

Building robust manufacturing inventory management software requires careful selection of appropriate technologies. Our comprehensive guide on how to create an inventory management software outlines the development process from requirements analysis through deployment. The backend infrastructure typically leverages enterprise-grade technologies such as .NET Core or Java Spring Boot for application development, providing the stability and performance needed for mission-critical manufacturing systems.

Database solutions must support both relational and analytical workloads. PostgreSQL or Microsoft SQL Server serve as primary databases for transactional data, while Apache Kafka enables real-time data streaming for immediate inventory updates. For analytics and reporting, technologies like Apache Spark or Azure Data Factory process large volumes of historical data to generate insights for inventory optimization.

Frontend development utilizes modern frameworks such as React or Angular to create responsive, user-friendly interfaces that work across desktop and mobile devices. API development follows RESTful principles with GraphQL integration for efficient data querying. Cloud infrastructure platforms like AWS, Azure, or Google Cloud provide the scalability and reliability needed for enterprise manufacturing environments.

Security and Compliance Considerations

Manufacturing companies must maintain strict security protocols to protect proprietary information and comply with industry regulations. Custom inventory management software for manufacturers incorporates role-based access controls, audit trails, and encryption protocols to ensure data integrity and regulatory compliance. Integration with existing security infrastructure maintains consistency with corporate security policies while providing granular control over inventory data access.

Security implementation utilizes industry-standard protocols including OAuth 2.0 for authentication, TLS 1.3 for data encryption in transit, and AES-256 for data at rest. Container orchestration platforms like Kubernetes provide secure deployment environments with automated scaling and failover capabilities. Integration with enterprise identity management systems such as Active Directory or LDAP ensures consistent access control across all manufacturing systems.

Compliance requirements vary significantly across manufacturing sectors, necessitating flexible configuration options within the software architecture. Food and beverage manufacturers require lot tracking and expiration date management, while pharmaceutical companies need serialization and chain of custody documentation. The technical architecture must accommodate these diverse requirements through configurable compliance modules and reporting capabilities.

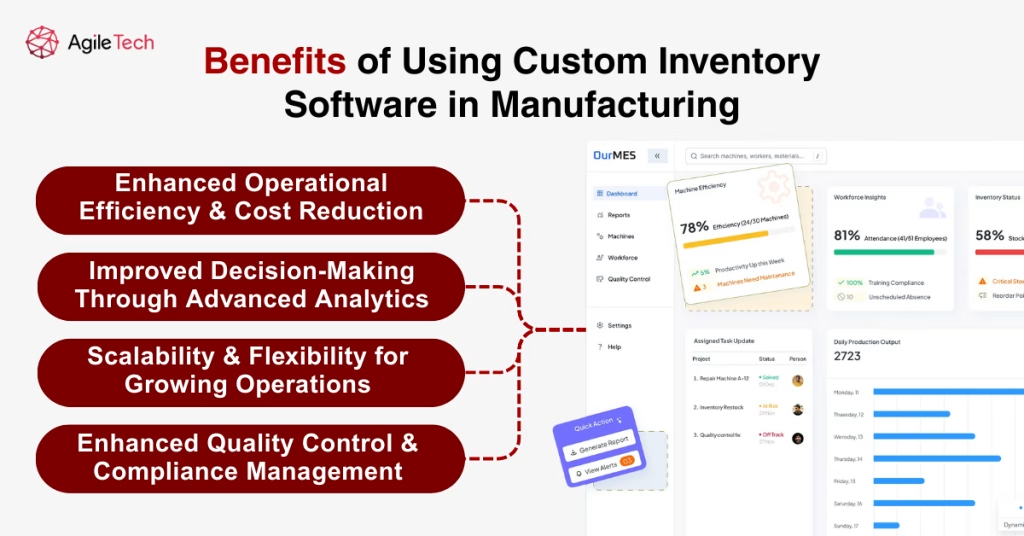

3. Benefits of Using Custom Inventory Software in Manufacturing

3.1. Enhanced Operational Efficiency and Cost Reduction

Custom inventory software for manufacturing delivers substantial operational improvements through automation and optimization. Automated reordering processes eliminate manual intervention while ensuring optimal inventory levels based on consumption patterns and lead times. This automation reduces administrative overhead while minimizing the risk of human error in inventory management processes.

Production efficiency improvements result from better material availability and reduced setup times. When inventory software integrates with production planning systems, manufacturers can optimize batch sizes, reduce changeover times, and minimize material waste. These improvements directly impact production costs while enhancing overall manufacturing throughput. The cumulative effect of these optimizations often results in significant cost reductions across manufacturing operations. Understanding inventory management software cost factors helps manufacturers evaluate the return on investment for custom solutions.

3.2. Improved Decision-Making Through Advanced Analytics

Data-driven decision-making becomes possible when manufacturing inventory management software provides comprehensive analytics and reporting capabilities. Real-time dashboards offer immediate visibility into inventory levels, consumption rates, and procurement status. Learning how inventory management software works enables manufacturers to maximize the value of their investment through proper utilization of system capabilities. This visibility enables manufacturing managers to make informed decisions about production scheduling, capacity planning, and resource allocation.

Predictive analytics capabilities transform historical data into future insights, enabling proactive inventory management strategies. Demand forecasting algorithms analyze market trends, seasonal patterns, and customer behavior to optimize inventory procurement and production planning. These capabilities help manufacturers maintain optimal inventory levels while minimizing carrying costs and stockout risks.

3.3. Scalability and Flexibility for Growing Operations

Custom inventory software for manufacturing company operations provides the scalability needed to support business growth. The modular architecture allows manufacturers to add functionality as their operations expand, whether through new product lines, additional manufacturing facilities, or increased production volumes. This scalability ensures that the software investment continues to deliver value as the business evolves.

Configuration flexibility enables manufacturers to adapt the software to changing business requirements without extensive redevelopment. Custom workflows, reporting structures, and integration capabilities can be modified to accommodate new processes, regulatory requirements, or market conditions. This flexibility reduces the total cost of ownership while ensuring long-term viability of the software investment.

3.4. Enhanced Quality Control and Compliance Management

Integration between inventory management and quality control systems creates comprehensive traceability throughout the manufacturing process. Batch tracking capabilities enable manufacturers to identify and isolate quality issues quickly, minimizing the impact on production and customer satisfaction. This integration supports continuous improvement initiatives by providing detailed analysis of quality trends and their correlation with inventory management practices.

Compliance management becomes streamlined when inventory software incorporates regulatory requirements into standard workflows. Automated documentation generation ensures that all necessary records are maintained according to industry standards. This automation reduces compliance costs while minimizing the risk of regulatory violations that could disrupt manufacturing operations.

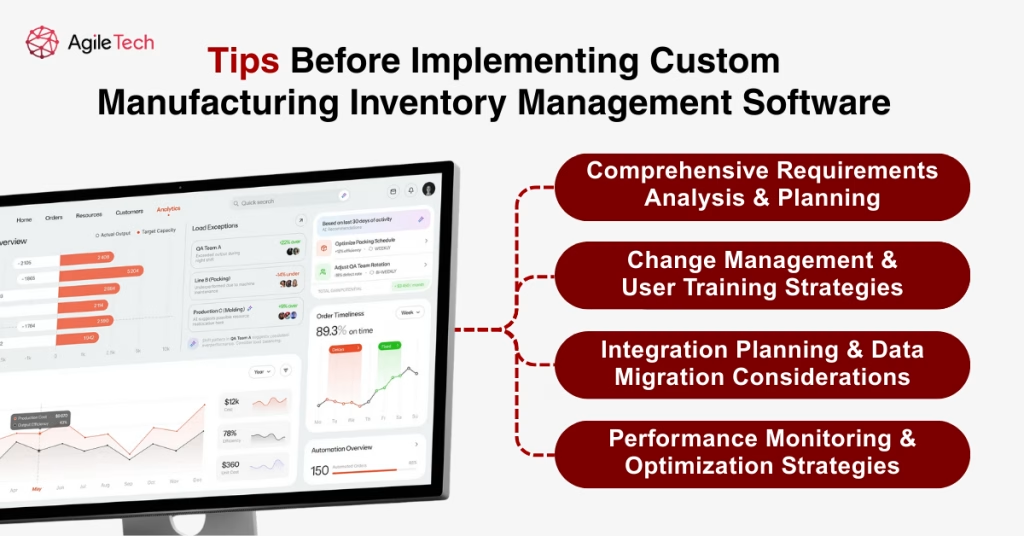

4. Tips Before Implementing Custom Manufacturing Inventory Management Software

4.1. Comprehensive Requirements Analysis and Planning

Successful implementation of inventory software for manufacturing begins with thorough requirements analysis. Manufacturing companies should conduct detailed assessments of their current inventory management processes, identifying pain points, inefficiencies, and areas for improvement. This analysis should include input from all stakeholders including production managers, warehouse personnel, procurement teams, and quality control staff.

The requirements gathering process must consider both immediate needs and future growth projections. Manufacturing companies should evaluate their product portfolio expansion plans, facility growth strategies, and market development initiatives to ensure the software can accommodate these changes. This forward-thinking approach prevents costly modifications or system replacements as the business evolves.

4.2. Change Management and User Training Strategies

Implementation success depends heavily on effective change management and comprehensive user training programs. Manufacturing employees often have established workflows and may resist changes to familiar processes. Early engagement and clear communication about the benefits of the new system help build support for the implementation project.

Training programs should be tailored to different user roles and responsibilities within the manufacturing organization. Production operators require different training than procurement managers or quality control personnel. Hands-on training sessions using actual production data help users understand how the new system will improve their daily work processes. Ongoing support and refresher training ensure that users can maximize the system’s capabilities.

4.3. Integration Planning and Data Migration Considerations

Successful integration requires careful planning and coordination between the new inventory software and existing manufacturing systems. Data mapping exercises identify how information flows between systems and where integration points are needed. This planning phase should include contingency plans for potential integration challenges and data quality issues.

Data migration represents one of the most critical aspects of implementation. Manufacturing companies typically have extensive historical data that must be accurately transferred to the new system. Data cleansing and validation processes ensure that only accurate, relevant information is migrated. Testing procedures verify that all data relationships and business rules function correctly in the new system environment.

4.4. Performance Monitoring and Optimization Strategies

Post-implementation monitoring ensures that the inventory software continues to deliver expected benefits. Key performance indicators should be established before implementation to measure success and identify areas for improvement. These metrics might include inventory turnover rates, stockout frequency, carrying cost reductions, and order fulfillment accuracy.

Regular system performance reviews help identify optimization opportunities and ensure that the software continues to meet evolving business requirements. Manufacturing companies should establish formal review processes that include all stakeholders and focus on both technical performance and business outcomes. These reviews provide valuable input for system enhancements and future development priorities.

5. Choosing AgileTech for Tailored Manufacturing Inventory Tracking Software

AgileTech specializes in building inventory software for manufacturing industry leaders across diverse sectors. Our tailored solutions address specific operational workflows and support various production methodologies like lean and JIT.

We offer full-cycle development, from requirement analysis to deployment and support, ensuring long-term value through scalability, real-time tracking, and system integration.

Client testimonials and case studies provide evidence of our ability to deliver measurable results through custom inventory management software development. These success stories demonstrate the tangible benefits that manufacturers achieve when they partner with AgileTech for their inventory software needs. Our commitment to client success ensures that we remain focused on delivering solutions that provide lasting value to your manufacturing operations.

With a future-ready tech stack, secure architecture, and expertise in IoT and AI integration, AgileTech delivers manufacturing inventory tracking software that evolves with your business needs.