ERP Procurement: Optimize ERP System Purchasing with Clear Steps & Roles

In an increasingly digital economy, ERP procurement is no longer a backend task; it’s a strategic enabler. The way businesses approach ERP system purchasing can determine their long-term operational efficiency and competitiveness. This guide offers a comprehensive overview of the ERP procurement process, the critical roles involved, and how to maximize value from ERP software for procurement.

1. Introduction to ERP Procurement

ERP procurement refers to the process of sourcing, selecting, and implementing Enterprise Resource Planning (ERP) systems to streamline purchasing and procurement operations. Unlike traditional methods, ERP purchasing offers greater transparency, centralized control, and integration across departments. Businesses today are transitioning from fragmented legacy systems to comprehensive ERP software for procurement to stay competitive and agile.

Traditional procurement methods often suffer from inefficiencies like duplicated data, delayed approvals, and a lack of visibility. ERP system procurement addresses these issues by automating tasks, standardizing workflows, and integrating procurement with other business functions, such as finance, inventory, and production.

Read more: What is Procurement Software? Complete Guide to Modern Procurement Solutions

2. Key Benefits of ERP Software for Procurement

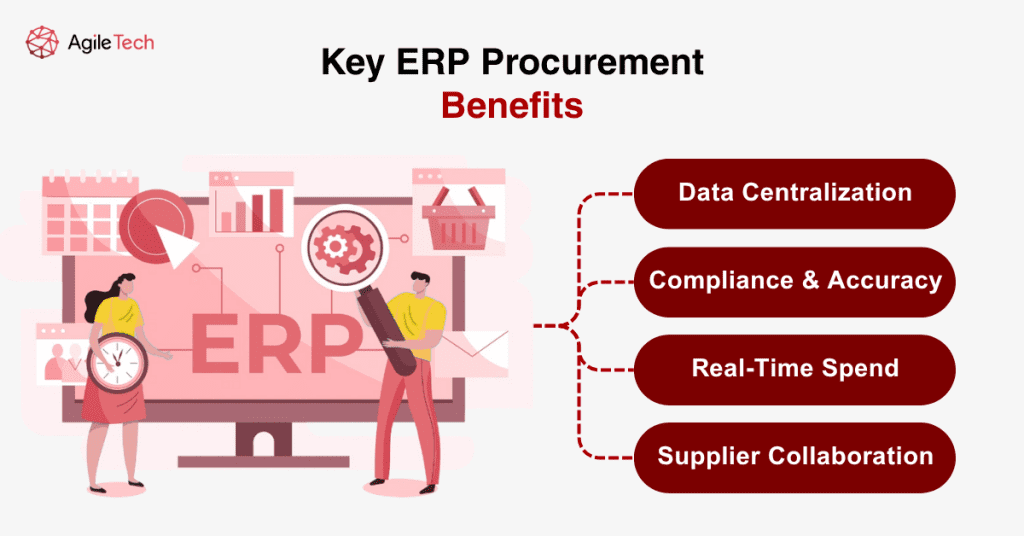

2.1. Centralization of Procurement Data

Implementing ERP software for procurement delivers a wide array of strategic and operational benefits that extend far beyond simple automation. One of the most critical advantages is the centralization of data. In many organizations, procurement data is scattered across spreadsheets, emails, and disconnected systems. With ERP, all supplier contracts, purchase requests, order histories, and vendor performance metrics are housed in one centralized platform. This centralized repository ensures consistency, reduces duplication, and makes it easier to generate consolidated reports for strategic decisions.

A real-world example comes from a mid-sized electronics manufacturer in Germany, which reduced procurement-related email volume by 60% after ERP implementation. This improvement was made possible by consolidating supplier communication and documentation within a single system that allowed authorized stakeholders to access procurement data without delays or misunderstandings.

2.2. Improved Accuracy and Compliance

Process accuracy and compliance are cornerstones of a high-performing procurement operation. Traditional manual procurement often results in data entry errors, duplicate records, and missed deadlines for contract renewals or supplier audits. ERP purchasing systems mitigate these risks through automation, built-in validation rules, and audit trails.

For instance, by utilizing an ERP system with automated three-way matching between purchase orders, invoices, and delivery receipts, companies can reduce invoice discrepancies. SAP’s 2022 benchmarking study revealed that organizations using automated procurement workflows experienced a 48% reduction in invoice processing errors within the first year. This level of accuracy ensures that companies comply with internal policies and external regulations such as SOX (Sarbanes-Oxley Act) or ISO procurement standards.

Moreover, compliance is enhanced with permission-based access control and pre-approved supplier catalogs. Procurement officers can define workflows where only authorized personnel are allowed to release purchase orders, making it easier to enforce segregation of duties and eliminate maverick buying.

2.3. Real-Time Spend Visibility and Cost Control

One of the most powerful benefits of ERP system procurement is its ability to provide real-time spend visibility. This capability is particularly important for CFOs and procurement leaders who need to maintain tight control over budgets across departments, locations, or business units.

ERP dashboards allow finance teams to monitor ongoing purchases against approved budgets, generate spend analysis reports, and identify anomalies such as duplicate orders or unapproved vendors. For example, a retail chain managing procurement across 80 store locations uses ERP to visualize daily, weekly, and monthly spending patterns. By setting threshold alerts, the system flags any budget overshoot or unusual procurement activity in real time, enabling rapid corrective action.

These insights support better forecasting and resource planning, allowing organizations to negotiate better pricing with suppliers or consolidate orders to leverage volume discounts. Over time, these savings directly improve bottom-line profitability.

2.4. Stronger Supplier Collaboration

Lastly, ERP software enhances supplier collaboration, which is essential for a stable and responsive supply chain. Modern ERP platforms include supplier relationship management (SRM) tools that foster transparency and communication.

Suppliers can access real-time updates on purchase orders, invoice statuses, and delivery schedules through self-service portals. This eliminates the need for constant follow-ups and helps both parties align on expectations. For example, a food and beverage distributor reduced late deliveries by 40% by offering suppliers a portal that showed real-time delivery timelines and automated alerts.

ERP also enables organizations to evaluate suppliers based on KPIs such as delivery accuracy, quality ratings, and responsiveness. This data supports strategic sourcing decisions and strengthens partnerships with top-performing vendors. In the long term, ERP procurement systems help create a more agile and resilient procurement network that can adapt quickly to disruptions or shifts in demand.

3. Step-by-Step ERP Procurement Process Implementation

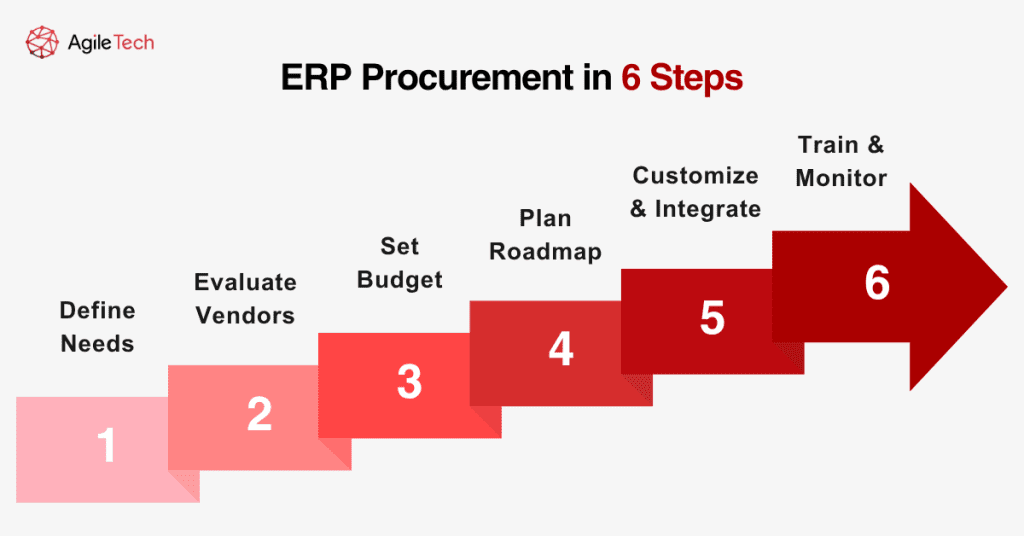

A successful ERP system procurement process requires a structured and strategic approach. The following six steps outline a best-practice framework that organizations can follow to ensure smooth implementation and high ROI.

Step 1: Define Procurement Needs and Goals

The first and most foundational step is to perform a comprehensive procurement audit. This involves mapping existing workflows, identifying inefficiencies, and defining success criteria. Organizations should gather insights from end-users, procurement managers, and IT specialists. For example, a healthcare organization looking to adopt ERP may realize its biggest bottlenecks are manual vendor onboarding and non-standardized requisitions. Knowing this helps tailor ERP requirements accordingly.

Well-articulated goals such as reducing lead time by 25%, improving supplier compliance, or enabling e-sourcing help narrow down ERP features and ensure that system selection is rooted in business priorities.

Step 2: Evaluate and Shortlist ERP Vendors

With objectives in place, the next step is market research and vendor evaluation. Organizations should look for ERP software for procurement that matches both functional needs and strategic goals. Key criteria include procurement-specific capabilities like purchase requisition automation, contract lifecycle management, vendor evaluation, and integration readiness with finance and warehouse systems.

A strong evaluation process typically involves sending a Request for Proposal (RFP), setting up demo sessions, and scoring vendors on metrics such as cost, flexibility, support, and deployment timeline. For instance, a logistics firm might prefer a cloud-based ERP with strong mobile functionality to support field operations.

Step 3: Budgeting and Internal Approval

ERP system purchasing is a significant investment, and clear financial planning is essential. Cost elements include software licensing, implementation services, hardware upgrades (if on-premises), training, and post-launch support. A transparent budget also accounts for hidden costs like data migration and potential downtime.

Finance teams must collaborate with project leads to create ROI projections. A good practice is to align cost benefits, such as reduced maverick spending or decreased procurement cycle time, with financial KPIs. These forecasts strengthen the business case and help secure executive approval faster.

Step 4: Plan the Implementation Roadmap

Once the vendor is selected and the budget approved, planning the implementation roadmap is critical. This roadmap serves as a shared guide for project timelines, resource allocation, and communication.

Key milestones often include: system design workshops, user acceptance testing (UAT), go-live preparation, and post-launch evaluation. A phased rollout starting with core procurement functions and expanding into contract or inventory modules helps minimize disruption.

Project teams should also define KPIs, such as PO cycle time or supplier responsiveness rate, to track procurement process implementation outcomes.

Step 5: Customize, Test, and Integrate

Customization ensures that the ERP solution reflects the organization’s unique procurement model. For example, a manufacturing firm may require approval routing based on spend thresholds or supplier type. These custom workflows should be carefully configured and documented.

Before going live, end-to-end testing is crucial. Test scenarios should replicate real-world transactions like multi-level approvals, three-way invoice matching, or exception handling. Simultaneously, integration with existing systems such as accounting software or warehouse management must be validated to ensure data consistency and eliminate silos.

Step 6: Train Users and Monitor Adoption

Even the most powerful ERP solution can fail without proper adoption. Training programs must be role-based, hands-on, and supported with documentation or videos. Conducting live simulations helps users become familiar with the interface and workflows.

To sustain engagement, appoint ERP champions in each department who can guide peers and provide first-line support. Post-launch, organizations should use analytics dashboards to monitor usage patterns, identify drop-offs, and schedule refresher training if needed.

Regular audits and feedback loops ensure that the ERP system continues to evolve with business needs, making procurement more agile and effective over time.

Read more: What Is a Procurement System? Definition, Benefits, and Key Features

4. Key Roles and Responsibilities in ERP Procurement

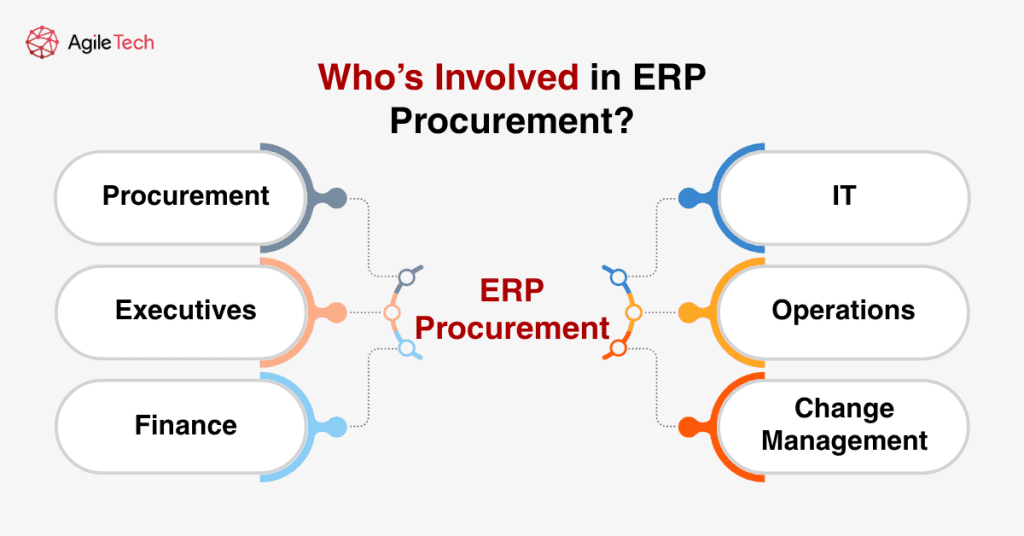

ERP procurement success hinges on the collaboration of multiple departments, each with a defined role in ensuring the system is chosen, implemented, and adopted effectively. Below are the core roles and their responsibilities within the ERP system procurement process.

4.1. Procurement Leadership

The procurement department serves as the driving force behind ERP procurement. Its leaders are responsible for identifying system requirements, managing vendor relationships, and ensuring alignment between the ERP solution and procurement goals. They define the business case, contribute to vendor evaluations, and often act as primary stakeholders throughout the implementation lifecycle.

Procurement leaders also ensure that sourcing policies and supplier engagement strategies are reflected in the system design. Their insight into day-to-day operations is essential for configuring approval workflows, setting compliance rules, and validating procurement reports within the ERP.

4.2. Executive and Strategic Planning Teams

Executives and strategic planners ensure that the ERP procurement initiative aligns with long-term business objectives. They provide oversight, approve budgets, and allocate resources. Their strategic vision helps prioritize key functionalities and guides decision-making when trade-offs are required.

These teams also play a critical role in gaining enterprise-wide support for ERP system purchasing. Their sponsorship ensures the project receives the attention and funding it needs to succeed.

4.3. Finance Department

The finance team ensures that ERP procurement is aligned with corporate financial controls and budgetary requirements. They collaborate closely with procurement to set cost baselines, define approval limits, and integrate procurement data into financial reporting tools.

Finance also assists in evaluating return on investment (ROI) for ERP software for procurement, modeling savings from automation, reducing errors, and better supplier negotiations.

4.4. IT and Technical Teams

IT departments handle the technical backbone of ERP system procurement. Their primary responsibilities include infrastructure planning, integration with existing systems (such as inventory or CRM platforms), data migration, and cybersecurity compliance.

They work alongside vendors to customize ERP modules, resolve configuration issues, and ensure system scalability. IT also provides post-launch technical support and manages software updates and licenses.

4.5. Operations and Supply Chain Stakeholders

Operations and supply chain teams are key users of procurement modules. Their feedback informs the design of requisition processes, inventory control, and supplier lead-time tracking.

These users rely on the ERP system to maintain continuity in materials sourcing, logistics coordination, and inventory replenishment. As end-users, their early engagement ensures the ERP solution supports real-world operational requirements.

4.6. Change Management and Training Leads

Change managers and training leads are tasked with preparing the workforce for ERP adoption. They develop training plans, manage communications, and collect feedback during rollout phases.

These individuals play a crucial role in driving user adoption and ensuring long-term success. By creating educational content, facilitating onboarding sessions, and offering ongoing support, they help build confidence and proficiency among employees.

5. How AgileTech Supports Your ERP Procurement Journey

At AgileTech, we specialize in delivering custom ERP solutions that drive procurement transformation. Whether you’re just starting your ERP system purchasing journey or looking to optimize an existing system, we provide end-to-end services that align with your business goals.

Our team begins by mapping your current procurement process and identifying inefficiencies. We then design and implement ERP software for procurement tailored to your workflows, approval chains, and reporting needs. AgileTech ensures seamless integration with your finance, inventory, and logistics systems for maximum efficiency.

Beyond deployment, AgileTech offers extensive user training and post-launch support. Our continuous monitoring and optimization services help you adapt to market changes and scale with confidence. Clients across manufacturing, retail, and logistics have reported up to 35% improvements in procurement cycle time with AgileTech ERP solutions.

Conclusion

ERP procurement is more than a technology upgrade; it’s a strategic investment. By following a structured procurement process implementation and engaging the right internal roles, businesses can ensure a smooth ERP system purchasing journey.

With the right ERP software for procurement, organizations gain enhanced transparency, cost control, and supplier collaboration. AgileTech stands ready to support you with tailored solutions that empower long-term procurement excellence.

Investing in ERP purchasing today sets the stage for smarter, faster, and more resilient operations tomorrow nội dung test