What Is Inventory Management Software and Why Do Businesses Need It?

Modern businesses face increasing complexity in managing stock levels, supply chains, and customer demands. Inventory management software provides the technological foundation to streamline operations, reduce costs, and enhance decision-making capabilities across all business functions.

- 1. What Is Inventory Management Software?

- 2. Types of Inventory Management Systems

- 3. How Does Inventory Management Software Work?

- 4. Benefits of Implementing a Tailored Inventory Management System

- 5. The Future of Custom Inventory Management Software

- 6. Collaborate with AgileTech on Custom Inventory Solutions

- 7. Conclusion

1. What Is Inventory Management Software?

Inventory management software represents a comprehensive digital solution designed to track, monitor, and control a company’s stock levels across multiple locations and channels. This sophisticated technology automates the complex processes involved in managing inventory, from procurement and storage to sales and distribution.

When businesses ask “What is inventory management software?” they are seeking to understand a system that serves as the central nervous system for their supply chain operations. The software provides real-time visibility into stock levels, automates reorder processes, and generates detailed analytics that inform strategic business decisions.

An effective inventory management system encompasses several critical components that work together to create a seamless operational framework. The software integrates with existing business systems, including point-of-sale terminals, accounting software, and enterprise resource planning platforms, creating a unified ecosystem that eliminates data silos and reduces manual errors.

Key Features of Effective Inventory Management

Modern inventory management solutions incorporate numerous sophisticated features that address the diverse needs of contemporary businesses. Understanding these capabilities helps organizations evaluate what is the inventory management system that best suits their operational requirements.

- Real-Time Inventory Tracking and Visibility

- Automated Reorder Point Management

- Multi-Location and Multi-Channel Support

- Comprehensive Reporting and Analytics

- Supplier and Vendor Management Integration

- Barcode and RFID Technology Support

- Integration with Accounting and ERP Systems

- Mobile Accessibility and Cloud-Based Architecture

- Quality Control and Compliance Management

For a comprehensive analysis of these features and their implementation strategies, businesses can explore detailed guidance in our dedicated resource about inventory management system software features.

2. Types of Inventory Management Systems

Understanding the various types of inventory management systems available enables businesses to select the most appropriate solution for their specific operational requirements. Each type offers distinct advantages and is suited to different business models and industry sectors.

2.1. Perpetual Inventory Systems

Perpetual inventory systems provide continuous, real-time tracking of inventory levels throughout all business operations. These systems automatically update stock quantities as transactions occur, ensuring that inventory records remain current and accurate. This approach is particularly beneficial for businesses with high transaction volumes or complex supply chains that require immediate visibility into stock levels.

2.2. Periodic Inventory Systems

Periodic inventory systems conduct regular, scheduled inventory counts to update stock records. While less technologically intensive than perpetual systems, periodic approaches can be cost-effective for businesses with stable inventory patterns and lower transaction volumes. These systems require manual counting processes but may be suitable for smaller operations with limited technological infrastructure.

2.3. Hybrid Inventory Management Solutions

Hybrid solutions combine elements of both perpetual and periodic systems, allowing businesses to customize their approach based on specific product categories or operational requirements. This flexibility enables organizations to optimize their inventory management strategy while balancing technological sophistication with operational practicality.

2.4. Cloud-Based Inventory Management Systems

Cloud-based inventory management systems solutions offer scalability, accessibility, and reduced infrastructure costs. These systems provide remote access to inventory data and can accommodate business growth without significant hardware investments. Cloud solutions also facilitate integration with other business systems and enable real-time collaboration across multiple locations.

2.5. On-Premise Inventory Management Systems

On-premise systems provide complete control over data security and system customization but require significant internal IT resources for maintenance and updates. These solutions may be preferred by businesses with specific security requirements or those operating in highly regulated industries where data control is paramount.

Different industries have unique inventory management requirements that influence system selection. Food service businesses benefit from specialized restaurant inventory management solutions that handle perishable goods and complex recipe tracking. Online businesses require robust inventory management e-commerce platforms that synchronize across multiple sales channels and integrate with shipping systems. Physical stores need comprehensive retail inventory management systems that coordinate between online and offline sales channels. Manufacturing companies require specialized inventory software for the manufacturing industry that manages raw materials, work-in-progress inventory, and finished goods throughout the production process.

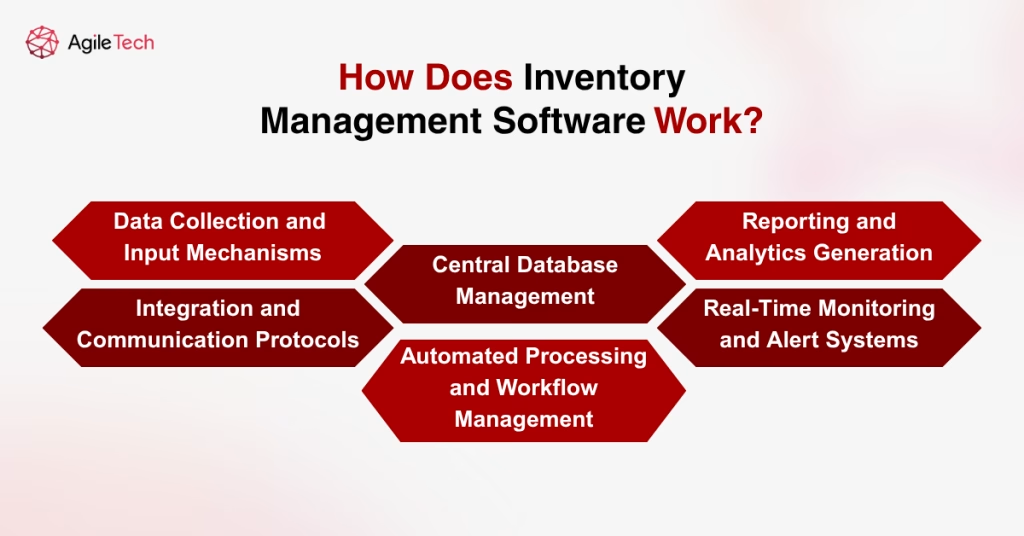

3. How Does Inventory Management Software Work?

Understanding how inventory management software works requires examining the complex technological processes that enable these systems to function effectively. The operational mechanics involve multiple interconnected components that work together to provide comprehensive inventory control. For businesses considering building their own solution, our comprehensive guide on how to create an inventory management software provides detailed technical specifications and development methodologies.

3.1. Data Collection and Input Mechanisms

Inventory management software begins with comprehensive data collection through various input mechanisms. Barcode scanners, RFID readers, and manual data entry systems capture product information, quantities, and location data. This information flows into the central database, where it becomes part of the comprehensive inventory record.

3.2. Central Database Management

The central database serves as the repository for all inventory-related information, including product specifications, quantities, locations, supplier details, and transaction history. This database employs sophisticated algorithms to process incoming data, update stock levels, and generate alerts based on predetermined parameters.

3.3. Automated Processing and Workflow Management

Automated processing capabilities handle routine inventory tasks without human intervention. These include generating purchase orders when stock levels reach reorder points, updating inventory records following sales transactions, and coordinating inventory transfers between locations. Workflow management ensures that these automated processes follow established business rules and approval procedures.

3.4. Integration and Communication Protocols

Modern inventory management systems communicate with other business systems through standardized integration protocols. These connections enable automatic data sharing between inventory management, accounting, customer relationship management, and enterprise resource planning systems. This integration eliminates data silos and ensures consistency across all business functions.

3.5. Real-Time Monitoring and Alert Systems

Real-time monitoring capabilities continuously assess inventory levels, demand patterns, and supply chain performance. The system generates automated alerts when predefined conditions are met, such as low stock levels, delayed shipments, or unusual demand patterns. These alerts enable proactive management and prevent potential operational disruptions.

3.6. Reporting and Analytics Generation

Advanced analytics engines process inventory data to generate comprehensive reports and insights. These analytical capabilities identify trends, forecast demand, evaluate supplier performance, and recommend optimization strategies. The reporting functionality provides stakeholders with the information needed to make informed strategic decisions.

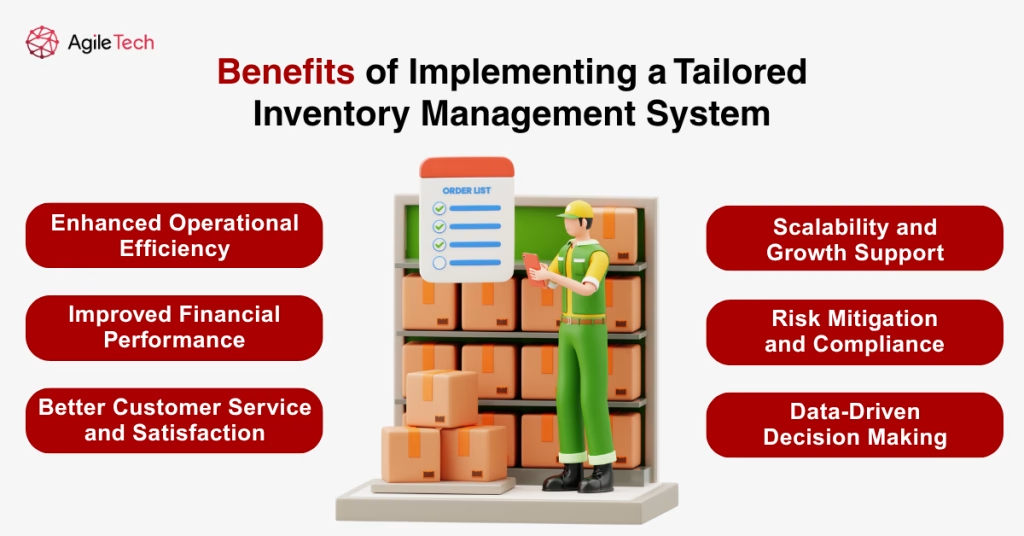

4. Benefits of Implementing a Tailored Inventory Management System

Implementing a customized inventory management system delivers substantial benefits that extend beyond simple stock tracking. These advantages impact multiple aspects of business operations and contribute to improved profitability and operational efficiency.

4.1. Enhanced Operational Efficiency

Custom inventory management systems streamline operations by automating routine tasks and eliminating manual processes that are prone to errors. This automation reduces the time and labor required for inventory management while improving accuracy and consistency across all operations. The efficiency gains enable staff to focus on higher-value activities that contribute directly to business growth.

4.2. Improved Financial Performance

Effective inventory management directly impacts financial performance through reduced carrying costs, minimized stockouts, and optimized purchasing decisions. By maintaining optimal stock levels, businesses can reduce the capital tied up in excess inventory while ensuring adequate supply to meet customer demand. This balance improves cash flow and enhances overall financial performance. Organizations evaluating implementation should consider our detailed analysis of inventory management software cost factors to make informed budget decisions.

4.3. Better Customer Service and Satisfaction

Reliable inventory management ensures product availability and enables accurate delivery commitments to customers. When businesses can consistently fulfill orders and provide accurate information about product availability, customer satisfaction improves significantly. This reliability builds customer loyalty and supports business growth through positive customer experiences.

4.4. Scalability and Growth Support

Custom inventory management systems can be designed to accommodate business growth and changing operational requirements. As businesses expand into new markets, add product lines, or increase transaction volumes, the system can scale to support these developments without requiring complete replacement. This scalability protects the initial investment while supporting long-term business objectives.

4.5. Risk Mitigation and Compliance

Advanced inventory management systems help businesses mitigate risks associated with stock shortages, excess inventory, and regulatory compliance. By providing accurate tracking and comprehensive documentation, these systems support audit requirements and help businesses maintain compliance with industry regulations. Risk mitigation capabilities protect businesses from potential losses and regulatory penalties.

4.6. Data-Driven Decision Making

Comprehensive inventory management systems generate valuable data that supports strategic decision-making across all business functions. The analytical capabilities enable businesses to identify opportunities for improvement, optimize supplier relationships, and develop more effective inventory strategies. This data-driven approach leads to better business outcomes and competitive advantages.

5. The Future of Custom Inventory Management Software

The evolution of inventory management technology continues to accelerate, driven by advances in artificial intelligence, machine learning, and Internet of Things technologies. These developments promise to further enhance the capabilities and effectiveness of inventory management systems solutions.

Artificial Intelligence and Machine Learning Integration

Artificial intelligence and machine learning technologies are increasingly being integrated into inventory management systems to provide predictive analytics and autonomous decision-making capabilities. These technologies can analyze historical data, market trends, and external factors to forecast demand more accurately and optimize inventory strategies automatically.

Internet of Things and Smart Inventory Tracking

Internet of Things technology enables the deployment of smart sensors and connected devices throughout the supply chain. These devices can provide real-time data on inventory levels, environmental conditions, and product status without human intervention. This connectivity enhances visibility and enables more precise inventory control.

Blockchain Technology for Supply Chain Transparency

Blockchain technology offers the potential for enhanced supply chain transparency and traceability. By creating immutable records of inventory transactions and movements, blockchain can improve trust between supply chain partners and provide comprehensive audit trails for regulatory compliance.

Advanced Analytics and Predictive Capabilities

Future inventory management systems will incorporate increasingly sophisticated analytics capabilities that can predict demand patterns, identify potential supply chain disruptions, and recommend proactive strategies. These predictive capabilities will enable businesses to anticipate challenges and opportunities before they impact operations.

Mobile and Remote Management Capabilities

The trend toward mobile and remote work continues to influence inventory management system design. Future solutions will provide enhanced mobile capabilities that enable comprehensive inventory management from any location, supporting distributed teams and flexible work arrangements.

6. Collaborate with AgileTech on Custom Inventory Solutions

At AgileTech Vietnam, we design custom inventory management systems tailored to your unique business needs. Whether you’re running a fast-scaling e-commerce business, managing a complex restaurant chain, or overseeing large-scale logistics operations, our team builds robust, scalable, and cloud-ready solutions.

One of our recent projects involved developing a custom IMS software solution that delivered tangible business results. The IMS software brought significant impacts to the client’s business: a 50% reduction in inventory errors through automated stock tracking and expiration date management; and a 75% faster decision-making process thanks to the interactive dashboard providing instant access to critical reports, enabling quicker and more strategic business decisions.

Our expertise in developing inventory management systems solutions includes:

- End-to-end inventory tracker system architecture

- Integration with POS, ERP, and accounting software

- Real-time data synchronization across multiple locations

- Automated alerts, AI forecasting, and smart dashboards

Let us help you stay ahead in your industry with the best inventory control software. Discover how AgileTech transforms operational chaos into streamlined clarity.

7. Conclusion

Modern businesses require sophisticated inventory management capabilities to compete effectively in today’s complex marketplace. Custom inventory management software provides the technological foundation necessary to optimize operations, reduce costs, and enhance customer service. By partnering with experienced technology providers like AgileTech, businesses can implement tailored solutions that address their specific requirements while providing the flexibility to adapt to future challenges and opportunities.

The investment in professional inventory management software represents a strategic decision that impacts all aspects of business operations. From improving operational efficiency and financial performance to enhancing customer satisfaction and supporting growth, the benefits of implementing the best inventory control software extend far beyond simple stock tracking. As businesses continue to face increasing complexity in their supply chains and customer demands, the value of sophisticated inventory management solutions will only continue to grow.