IoT Fleet Management: A Step-by-Step Implementation Guide for Software Development

IoT fleet management solutions are revolutionizing how logistics, manufacturing, and retail businesses manage delivery operations. Rather than relying on rigid, off-the-shelf tools, many organizations are turning to custom-built IoT fleet management software to gain real-time insights, automate maintenance, and optimize performance. In this comprehensive guide, we break down the process of building such a system, focusing on the software development side and how AgileTech can help.

- 1. What Is IoT Fleet Management and Why Does It Matter

- 2. Core Technologies Behind IoT Fleet Management

- 3. Why Do You Need IoT Technology for Fleet Management?

- 4. How to Implement IoT in Fleet Management: A Step-by-Step Guide

- 5. Development Lifecycle for Custom Fleet Software

- 6. Common Mistakes to Avoid

- Conclusion

1. What Is IoT Fleet Management and Why Does It Matter

1.1. Definition and Benefits

IoT fleet management involves integrating smart sensors, tracking devices, and software platforms to monitor and control vehicle fleets in real time. These systems provide operational transparency, predictive maintenance, driver behavior analysis, and route optimization.

Businesses benefit through reduced fuel costs, increased asset uptime, safer driving practices, and better resource allocation. Most importantly, a custom solution can adapt to your unique workflows and regulatory requirements.

Imagine a retailer with dozens of daily deliveries relying on outdated spreadsheets transitioning to IoT software that provides the same leap in control and accuracy as going from paper maps to Google Maps.

1.2. Use Cases Across Industries

In logistics, IoT is used for real-time shipment tracking, route efficiency, and temperature monitoring in cold-chain operations. For instance, a frozen goods distributor using live temperature data ensures compliance and prevents spoilage.

Retailers integrate fleet data with inventory and delivery management for last-mile visibility. A fashion brand, for example, can use real-time tracking to update customers on package locations and optimize stock replenishment.

Manufacturers sync outbound logistics with production timelines, minimizing bottlenecks and costly downtime. Public sector fleets like snowplows or garbage trucks use IoT for transparent service and efficient route planning.

| Industry | Use Case Examples | Key Benefit |

| Logistics | Route optimization, cold-chain tracking | On-time delivery, temperature compliance |

| Retail | Inventory sync, last-mile visibility | Customer satisfaction, stock accuracy |

| Manufacturing | Production-delivery coordination | Reduced downtime, supply flow |

| Public Services | Waste collection, snow plows, emergency dispatch | Transparency, faster response |

2. Core Technologies Behind IoT Fleet Management

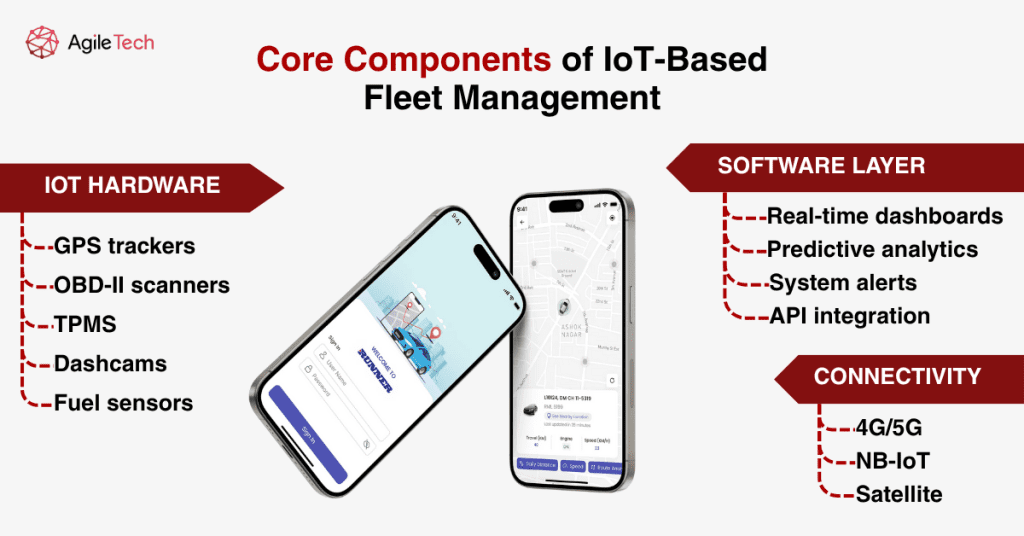

2.1. IoT Devices and Sensors

Key hardware includes GPS trackers for vehicle location, OBD-II (On-Board Diagnostics) scanners for engine diagnostics, and dashcams to monitor driver behavior. TPMS (Tire Pressure Monitoring Systems) and load sensors ensure safety and compliance, while fuel sensors detect abnormal usage or leakage.

Without these sensors, a logistics company may remain unaware of excessive idling or engine faults until costly delays occur. With IoT, these insights are delivered before issues escalate.

2.2. Connectivity and Data Transmission

Urban fleets typically use 4G/5G, while rural operations require NB-IoT (Narrowband IoT) or satellite networks. Reliable connectivity ensures that fleet managers are immediately alerted when vehicles deviate from routes or encounter mechanical issues.

Picture a scenario where a delivery truck breaks down on a remote highway. IoT enables real-time alerts and automated rerouting, avoiding delays and maintaining customer trust and SLA commitments.

2.3. Software Platforms and Dashboards

IoT platforms consolidate vehicle data into centralized dashboards. Managers can visualize real-time locations, assess route performance, and schedule maintenance based on usage patterns and thresholds.

A food delivery company handling over 100 routes per day, for example, benefits from dashboards that turn real-time data into action: rerouting during peak hours, predicting maintenance before failure, or assessing driver risk.

These platforms often feature advanced analytics capabilities powered by machine learning. Predictive models can flag high-risk vehicles, anticipate component failures, and even recommend optimal replacement schedules. For developers, building these tools means integrating APIs from telematics hardware, setting up secure data pipelines, and deploying dashboard interfaces customized for each operational role.

3. Why Do You Need IoT Technology for Fleet Management?

3.1. Evaluate Current Fleet Operations

Begin by auditing your fleet’s size, maintenance needs, and existing communication systems. Many companies uncover hidden costs such as unproductive idle time, duplicated route coverage, or late deliveries due to outdated schedules.

Gathering insights directly from dispatchers, drivers, and technicians helps highlight operational pain points. These interviews often expose practical problems that software can fix, from a lack of visibility on remote routes to unpredictable vehicle downtime.

This stage defines the baseline for future improvement, ensuring the system you build is based on reality, not assumptions. Software developers often conduct on-site discovery workshops to document user stories, business rules, and data requirements.

3.2. Set Clear Goals and KPIs

Setting goals like “cut fuel waste by 15%” or “achieve 98% route compliance” helps clarify software functionality. Retailers may tie KPIs to customer satisfaction (on-time delivery), while manufacturers focus on production-delivery sync.

IoT platforms can automatically track metrics like average vehicle downtime, route adherence, and even driver performance scores. These insights help managers make informed decisions and continuously refine fleet strategies.

During software development, these KPIs are embedded in dashboards and reports. Developers must build flexible filters, reporting modules, and alerting rules that reflect operational priorities and regulatory constraints.

3.3. Map Problems to IoT Capabilities

Delayed deliveries? Apply real-time GPS routing. Frequent engine breakdowns? Enable predictive maintenance dashboards. High fuel consumption? Use load sensors and idle monitoring.

By linking each issue to a specific IoT capability, your custom software becomes a targeted solution, not just a digital replica of existing problems. This approach drives adoption and maximizes ROI from day one.

To do this effectively, developers must collaborate with domain experts to identify which data streams are most relevant, build microservices around them, and ensure responsive UI that prompts action.

Read more: Fleet Management Software Development: Development, Challenges, and Tech Stack

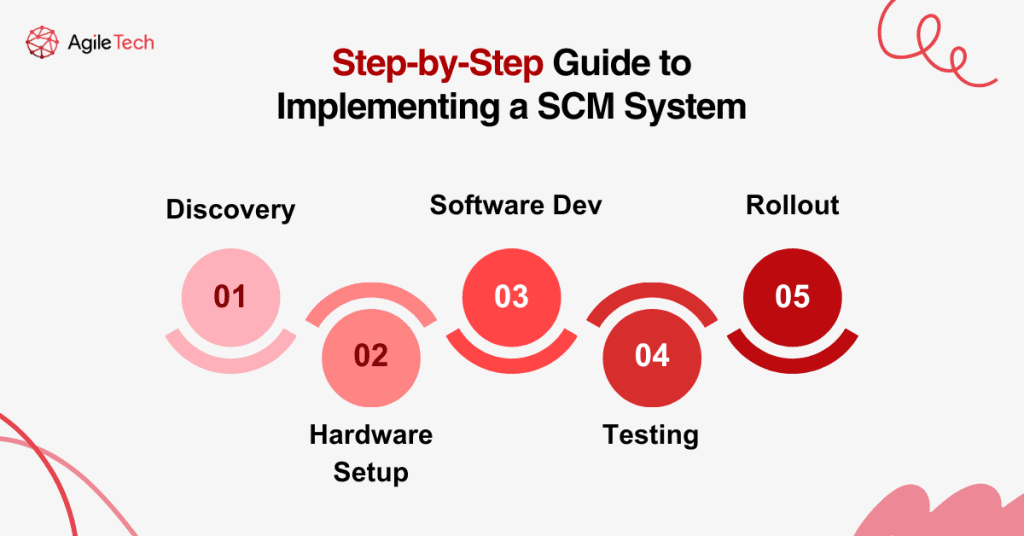

4. How to Implement IoT in Fleet Management: A Step-by-Step Guide

Step 1: Conduct Business and Technical Analysis

Start with a comprehensive discovery phase. Define your fleet structure, transportation goals, pain points, regulatory constraints, and digital maturity. At this stage, developers work closely with stakeholders to document use cases, identify data sources, and assess integration needs with ERP, WMS, or telematics systems.

Step 2: Choose the Right Technology Stack

Select hardware and software technologies that match your operating environments. For example, rugged GPS trackers and OBD-II sensors for trucks, combined with cloud platforms (AWS, Azure) for backend and frontend interfaces built with React or Angular. Ensure compatibility with connectivity standards like 4G/5G, NB-IoT, or satellite.

Step 3: Design the Architecture and UX

Design system architecture to include real-time data flow, alerting engines, analytics dashboards, and integration layers. The UI/UX design phase ensures that role-based access drivers, dispatchers, and managers see only relevant modules. Use wireframes and clickable prototypes to validate interface usability before coding.

Step 4: Develop Core Features Iteratively

Break development into sprints: begin with features like vehicle tracking and geofencing, then add driver behavior analytics, predictive maintenance, and reporting modules. Developers build backend APIs, real-time data processing (using Kafka, MQTT), and integrate third-party SDKs from sensor vendors.

Step 5: Deploy Pilot Version for Field Testing

Launch a limited version with a subset of vehicles. Monitor system responsiveness, alert accuracy, and user interaction. Gather structured feedback from fleet managers and drivers. Developers adjust features, fix bugs, and improve UX based on real-world use.

Step 6: Full Rollout and Team Training

Deploy the solution fleet-wide. Conduct comprehensive training for every user group. Provide documentation, support videos, and live sessions to ensure smooth onboarding. Monitor adoption and performance through analytics dashboards.

Step 7: Maintain, Scale, and Evolve

Continue to monitor system health and user engagement. Add new modules like carbon emission tracking or AI route prediction, as business needs evolve. AgileTech provides long-term support, updates, and performance optimization to keep your system future-ready.

5. Development Lifecycle for Custom Fleet Software

Agile development ensures flexibility. During the discovery phase, developers identify high-priority features. During prototyping, they validate UI/UX with users like dispatchers or drivers.

Continuous testing, paired with stakeholder feedback, keeps projects aligned. Frequent sprint reviews ensure timelines and budgets remain in control.

AgileTech provides dedicated project managers, progress visibility, and delivery milestones that align with your operations. From CI/CD pipelines to post-launch SLA monitoring, every development stage is backed by industry best practices.

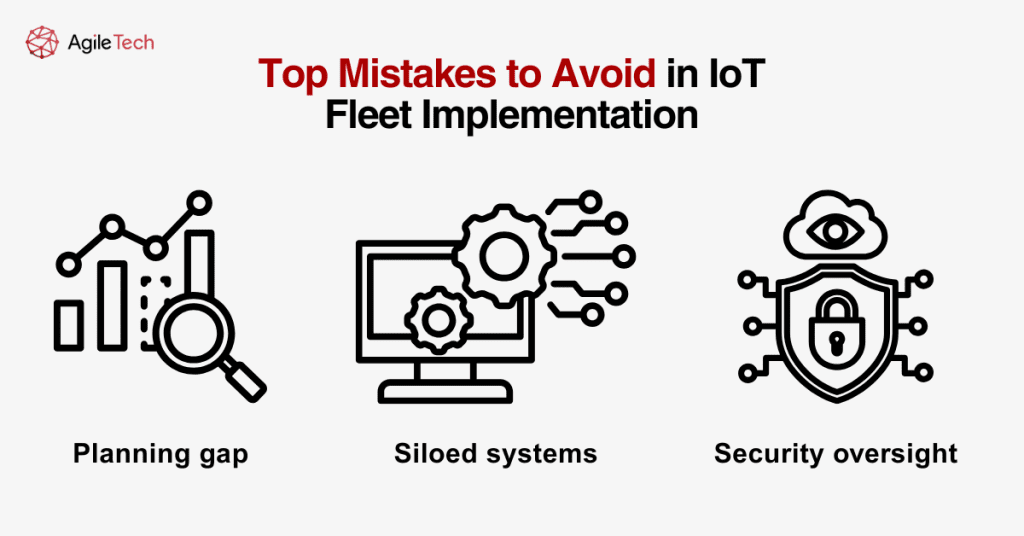

6. Common Mistakes to Avoid

6.1. Poor Planning and Lack of Alignment

Without aligning departments like IT, operations, and compliance, even the best tools will face friction. A food retailer implementing IoT failed to sync its CRM and faced duplication in order updates, a costly oversight.

Avoid this by appointing cross-functional champions and ensuring all systems and departments speak the same data language.

6.2. Overlooking Security and Compatibility

IoT breaches can compromise vehicle routes, customer data, and driver identity. Enforce encryption, authentication, and access logs.

Compatibility across sensors, devices, and software stacks is equally vital. A failure to unify APIs could result in data silos, rendering real-time analytics impossible.

Conclusion

Implementing IoT fleet software means more than digital transformation; it means regaining control of your logistics. By integrating real-time data into every delivery, service route, or production cycle, you ensure consistency, cost-efficiency, and customer satisfaction.

At AgileTech, we specialize in building end-to-end IoT fleet management systems tailored to your environment, whether you’re in logistics, manufacturing, or retail. From planning to post-launch support, our solutions are designed to be scalable, secure, and future-ready. Let’s start your journey toward smarter fleet management. Contact AgileTech to explore your custom software development roadmap today.